A 12v relay works best in a 12-volt system. If used in a 24v system, too much power can cause issues. The relay might get too hot and stop working. This can damage it forever or make it fail completely. Using the wrong relay can also make your system less reliable. Always use a relay that matches the system's voltage. The wrong relay can harm your equipment and create safety problems.

Key Takeaways

-

Always pick a relay that matches your system's voltage. This prevents overheating and damage.

-

-

Use a voltage regulator to safely run a 12v relay in a 24v system.

-

-

Switching to a 24v relay is the easiest and safest fix.

-

-

Resistors can reduce voltage, but they are less reliable than regulators.

-

-

Ask an expert to make sure your system works safely and correctly.

Understanding Relays and Voltage Compatibility

What is a 12v relay and how does it work?

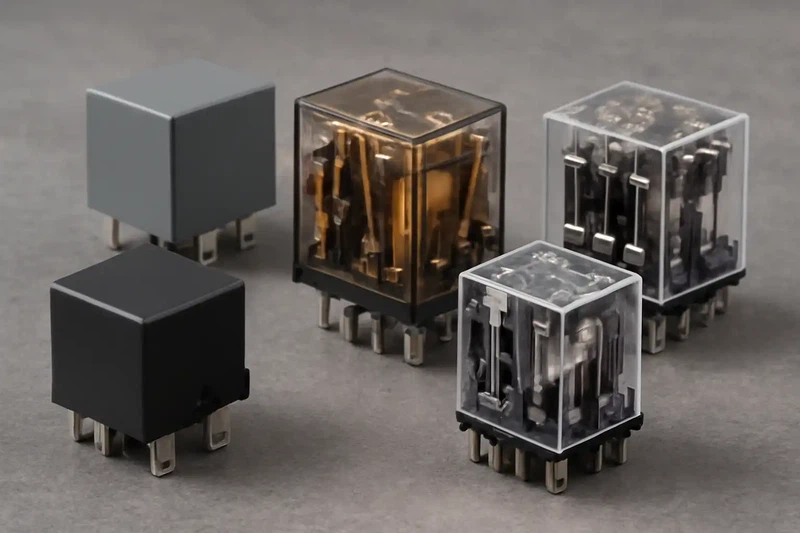

A 12v relay is a switch that controls bigger electrical loads. It uses an electromagnet to work. When electricity flows through the coil, it makes a magnetic field. This field moves a part inside the relay to open or close the circuit. This lets the relay control powerful devices with small signals.

A 12v relay works by using an electromagnet to move a switch. When electricity goes through the coil, it creates a magnetic field. This field moves a part that connects or disconnects the circuit. This helps control a circuit with little power while keeping the control and main circuits separate.

The table below shows the differences between a 12v relay and a 24v relay:

|

Specification |

12V Relay |

24V Relay |

|---|---|---|

|

Coil Voltage |

Made for 12V systems |

Made for 24V systems |

|

Coil Current |

Usually higher (e.g., 170 mA) |

Usually lower (e.g., 38 mA) |

|

Maximum Contact Current |

Common ratings: 25A, 30A, 60A |

Similar ratings available |

|

Coil Resistance |

Often around 80 ohms |

Can be higher, based on design |

|

Compatibility |

Good for car systems |

May work in lower voltage setups |

Why voltage compatibility is critical in 24 vdc systems

Matching voltage keeps the relay safe and working well. In 24 vdc systems, a 12v relay can overheat because of too much current. The higher voltage pushes more current than the coil can handle. This can break the relay and cause system problems. Using the right relay for the voltage avoids these issues and keeps your equipment reliable.

Common issues caused by mismatched voltage in relays

Using the wrong relay voltage can cause many problems:

-

The relay coil can overheat and get damaged forever.

-

-

Systems may shut down or act strangely.

-

-

Safety risks like electrical fires can happen.

-

History shows the dangers of mismatched relays. For example:

-

A solar plant had problems because of wrong relay settings.

-

-

A substation stopped working when a "close enough" relay was used, causing outages.

-

These examples show why using the right relay for your system is very important.

Risks of Using a 12v Relay in 24 vdc Systems

Overheating and potential damage to the relay

Using a 12v relay in a 24v system is risky. The relay coil, made for 12 volts, gets double the voltage. This extra voltage makes the coil pull too much current. Too much current causes the relay to overheat and break. Overheating can also bend or melt parts inside the relay. This damage makes the relay stop working completely.

Heat from the relay can harm nearby parts too. The extra heat might spread and cause other parts to fail. This can lead to expensive repairs or replacements. To prevent these issues, always use a relay that matches the system's voltage.

System malfunctions and reliability concerns

A wrong relay can make your system act up. For instance, a 12v relay in a 24v system might not work right. The high voltage can make the relay turn on and off randomly. This random switching messes up the system and makes it less reliable.

Over time, the relay may get worse. Studies show using the wrong voltage causes problems like:

-

Relays getting too hot and burning circuit boards.

-

-

Bad connections that damage equipment and lower performance.

-

-

Smart relays making errors, causing unexpected shutdowns.

-

These problems show why matching the relay to the system is key. A good system needs parts that work well together.

Safety hazards and long-term implications

Using a 12v relay in a 24v system can be dangerous. Overheating might start electrical fires, especially in high-power circuits. The heat could burn nearby materials, creating a fire risk.

There are also long-term dangers. A broken relay might fail off and on without being noticed. This could lead to big problems later. For example, a bad relay might cause important equipment to stop suddenly. This can disrupt work and increase accident risks.

Wrong relays can also harm costly equipment. Repeated failures from voltage mismatch can wear out other parts. To stay safe and protect your system, always pick a relay made for your voltage.

Solutions for Using a 12v Relay in a 24v System

Using a voltage regulator to lower 24V to 12V

A voltage regulator is a reliable way to use a 12v relay in a 24v system. It keeps the voltage steady, protecting the relay from damage. Regulators like the LM350 work well for this. This adjustable regulator handles high current and has a wide output range. Another good choice is the LM22680MRE-ADJ/NOPB. It can take up to 60V and lower it to a stable voltage. Its adjustable output (0.8V to 15V) makes it useful for powering a 12v relay.

Using a regulator protects the relay and keeps it working well. This is helpful for devices like 12v linear actuators needing exact voltage. Adding a regulator ensures your system stays reliable while safely using a 12v relay.

Adding a resistor to lower voltage for the relay

A cheaper option is adding a resistor in series with the relay coil. The resistor lowers the voltage to stop overheating and damage. Tests show reducing relay current to 67% drops power by 45%. Cutting current to 50% reduces power four times. This works if the resistor value matches or is half the coil resistance.

For example, a 200Ω resistor with a 9V battery-powered relay lowers voltage to 3V and current to 30mA. But you must check the relay's behavior during adjustments. Some relays may act oddly at lower voltages, affecting reliability. While less precise than a regulator, this method is good for cheap or temporary setups.

Replacing the 12V relay with a 24V relay

The easiest solution is swapping the 12v relay for a 24v one. A 24v relay handles higher voltage without changes. This avoids overheating, system issues, and safety risks. It also ensures long-term reliability and works well with your 24v system.

When replacing, pick a relay that fits your system's needs. Check the contact current rating and coil resistance. This ensures good performance and prevents problems like overloading. Using a 24v relay simplifies your setup and removes the need for extra parts like resistors or regulators.

Replacing the relay is vital for systems where safety and reliability matter most. It may cost more upfront but saves money on repairs later.

Using PWM to Control Voltage in Advanced Ways

Pulse Width Modulation (PWM) is a smart way to manage voltage. If you need to use a 12v relay in a 24v system, PWM can help. It controls how much voltage the relay coil gets. Instead of lowering the voltage directly, PWM changes how long the voltage stays "on" in each cycle. This keeps the relay safe from overheating or breaking.

How PWM Works

PWM turns the power on and off very quickly. The "on" time compared to the full cycle is called the duty cycle. For example, a 50% duty cycle means the power is on half the time. Changing the duty cycle adjusts the average voltage sent to the relay. A smaller duty cycle lowers the voltage, while a bigger one raises it.

This method saves energy because it avoids wasting power as heat. Unlike resistors, PWM only sends the needed power to the relay. This makes it a great choice for systems needing precision and energy savings.

Parts of a PWM Voltage Control System

To use PWM for controlling relay voltage, you need certain parts. Each part has an important job. Here's a simple list:

|

Part |

Job |

|---|---|

|

Microcontroller |

Creates the PWM signal and adjusts the duty cycle. |

|

PWM Control Circuit |

Makes sure the PWM signal works well with the power module. |

|

Power Drive Module |

Controls the current going to the relay coil based on the PWM signal. |

|

MOSFET |

Works as a strong switch to handle high currents. |

|

Excitation Coil |

Creates a magnetic field, with current adjusted for better control. |

These parts work together to give the relay the right voltage. The microcontroller makes the PWM signal. The MOSFET and power module handle the high currents, keeping the relay coil safe from overheating.

Why Use PWM for Relays?

PWM has many benefits for controlling relays:

-

Accuracy: You can adjust the voltage to fit the relay's needs. This helps the relay last longer and work better.

-

-

Energy Saving: PWM avoids wasting power by only sending what's needed. This makes it a cheaper option over time.

-

-

Adaptability: You can change the duty cycle to fit different relays or conditions. This makes PWM useful for many setups.

-

Using PWM lets you safely run a 12v relay in a 24v system. It keeps the system reliable and safe. But setting up PWM needs the right parts and some technical skills. If you're unsure, ask an expert to help you set it up properly.

Alternatives to Using a 12v Relay in 24 vdc Systems

Choosing a 24V relay for better compatibility

The easiest fix is using a 24V relay. This relay is made for higher voltage systems. It works without needing any changes or extra parts. A 24V relay stops problems like overheating or system failures. It keeps your system running safely and smoothly.

When picking a 24V relay, check its details. Look at the coil voltage and contact current rating. Make sure it matches your system's needs. For example, if your system uses high current, get a relay with a high contact rating. This ensures the relay works well in all situations.

A 24V relay might cost more at first. But it prevents damage and saves repair money later. It's the simplest way to keep your system safe and efficient.

Asking an expert for advice

If you're unsure what to do, ask an expert. A professional can check your system and suggest the best relay or changes. They can also explain advanced fixes like voltage regulators or PWM control.

Experts know how to spot problems early. They help keep your system safe and working well. While hiring a professional costs more, it avoids big mistakes. It also gives you confidence in your system's setup.

Weighing costs and benefits of changes

Before making changes, think about the costs and benefits. For example, adding a resistor or voltage regulator can let you use a 12v relay. But these fixes need extra parts and knowledge.

Compare the cost of these changes to buying a 24V relay. Often, switching to a 24V relay is cheaper and more reliable. Also, think about how changes affect your system over time. A good relay lowers maintenance and helps your equipment last longer.

By reviewing your options, you can pick the best choice for your system and budget.

Using a 12v relay in a 24v system is risky. It can cause overheating, system issues, and safety dangers. The safest choice is using a relay that matches the voltage. This keeps your system reliable, safe, and working well for a long time.

If changes are needed, try using voltage regulators or resistors. These can adjust the voltage but need careful setup. For example, solid-state relays block electromagnetic interference better. Traditional relays, however, show problems with visual signals. Solid-state relays may cost more at first.

Always think about safety when making changes. If unsure, ask an expert for help. This avoids mistakes and keeps your system running smoothly.

FAQ

What happens if you use a 12V relay in a 24V system without modifications?

The relay will overheat because it gets too much voltage. This can break the coil, make the relay stop working, or even cause safety problems like fires. Always use a relay that matches the system's voltage.

What is the safest way to use a 12V relay in a 24V system?

The safest way is to use a voltage regulator. It lowers the voltage from 24V to 12V. This keeps the relay safe from overheating or breaking.

Can you use a resistor to lower the voltage for a 12V relay?

Yes, you can use a resistor to reduce the voltage. But you need to calculate the resistor value carefully. This method is less reliable than using a voltage regulator.

Why is a 24V relay better for a 24V system?

A 24V relay is made for 24V systems. It works without extra parts and avoids overheating. This makes it safer and more dependable.

What should you consider when replacing a 12V relay with a 24V relay?

Check the new relay's details, like coil voltage and current rating. Make sure it fits your system to avoid problems. Picking the right relay ensures safety and good performance.