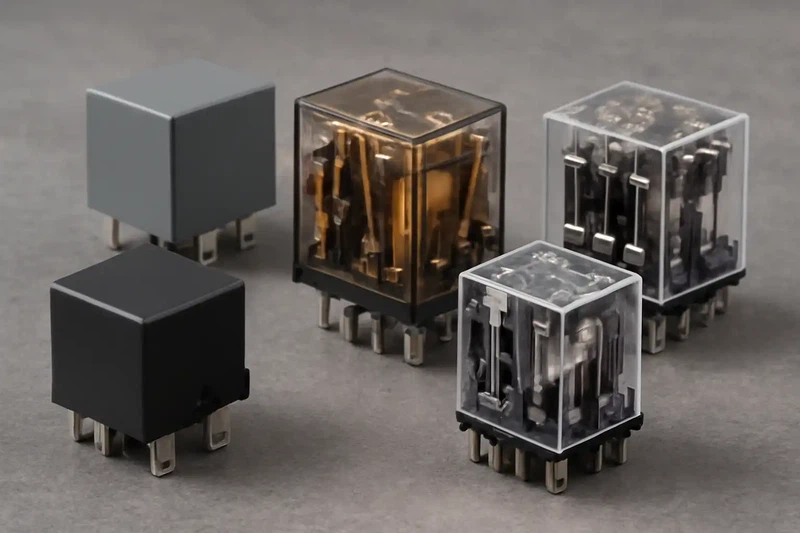

Plug-in relays are tools that control electric circuits. They work by opening or closing their contacts. These relays help manage electrical systems by switching, protecting, and connecting parts. You can see them used in cars, factories, and smart homes.

Cars are using more plug-in relays because they handle heat, voltage changes, and shaking in engines.

The market for these relays is growing fast. It will rise from USD 1.5 billion in 2024 to USD 2.8 billion by 2033 as more industries use automation and control systems.

Interposing relays help parts communicate smoothly in complex systems. This makes them very important.

Key Takeaways

Plug-in relays manage electric circuits by turning them on or off. They are important in cars, factories, and smart homes.

There are different kinds, like mechanical, solid-state, and time-delay. Each type does a specific job, so pick the right one.

Interposing relays link systems with different voltages. This makes them safer and easier to use in complex setups.

Plug-in relays are simple to replace. This saves time and money, helping systems work well without long delays.

Knowing relay types and uses can improve how systems work. It also makes them safer and more affordable to maintain.

Types of Plug-In Relays

Plug-in relays come in different types for various tasks. Knowing these types helps you pick the right one.

Mechanical Relays

Mechanical relays are the most common kind. They use parts like an electromagnet and moving contacts to control circuits. When turned on, the electromagnet pulls the contacts together to complete the circuit. These relays are dependable and affordable, making them useful for many jobs.

Applications:

Mechanical relays are used in cars for engine control and electronics. They are also important in factory machines and heating systems.

Advantages:

Simple design that's easy to fix.

Works well with high electrical currents.

Did you know? Mechanical relays are popular in cheaper markets, like gas-powered cars, because they last long and cost less.

Solid-State Relays

Solid-state relays (SSRs) don't have moving parts. They use special materials to switch circuits quickly. This makes them faster and tougher than mechanical relays. SSRs are great for jobs needing speed and reliability.

Applications:

Solid-state relays are used in energy systems, factory automation, and electric cars. They work well in places where switching happens often.

Advantages:

No moving parts, so they last longer.

Quiet and resistant to shaking or vibration.

Even though SSRs are becoming more common, mechanical relays are still preferred for their lower price.

Time-Delay Relays

Time-delay relays add a set delay before switching. This lets you control when circuits turn on or off. They are ideal for tasks needing exact timing.

Applications:

Time-delay relays are used in lights, motor control, and safety systems. For example, they can delay motors to avoid power spikes.

Advantages:

Better control and energy efficiency.

Useful for both factories and smart homes.

Pro Tip: Time-delay relays help save energy by controlling when devices start or stop.

Plug-in relays, whether mechanical, solid-state, or time-delay, have special uses. Each type solves specific problems, so you can find the best one for your needs.

Latching Relays

Latching relays, or bistable relays, are special because they stay in their position even when the power is off. Regular relays go back to their default state without power, but latching relays "remember" their last position. This makes them great for saving energy and specific uses.

How They Work:

Latching relays use a magnetic or mechanical latch to hold their state. A pulse of electricity changes the relay's position. Another pulse switches it back. This design means they don't need constant power to stay in place.

Applications:

Latching relays are used in systems where saving power is important, like:

Lighting Control: They keep lights on or off without using extra power.

Memory Circuits: These relays help circuits "remember" their state, useful in factories.

Home Automation: They control things like motorized blinds or garage doors.

Advantages:

Saves energy by not needing constant power.

Produces less heat, so they last longer.

Works well in battery-powered devices with limited energy.

Tip: Use a latching relay if your system needs to stay in one state during a power outage.

High-Amp Relays

High-amp relays are made to handle strong electrical currents. They are built with tough materials to manage heavy loads safely. These relays are important when regular relays can't handle the job.

What Makes Them Different:

High-amp relays have bigger contacts and better insulation. This helps them carry high currents without problems. Some also have features to stop damage from electrical sparks.

Applications:

High-amp relays are used in powerful systems, such as:

Automotive Systems: They control starters, headlights, and cooling fans.

Industrial Equipment: These relays run big motors, pumps, and compressors.

Renewable Energy Systems: They handle high currents in solar panels and wind turbines.

Advantages:

Manages high currents without overheating.

Strong and reliable for heavy-duty tasks.

Lowers the chance of electrical fires by safely handling large loads.

Did you know? High-amp relays are key in electric cars. They manage the strong currents needed for charging and running motors.

Knowing about latching and high-amp relays helps you pick the right one. Each type has special features for different jobs.

Categorization of Plug-In Relays

Knowing how plug-in relays are grouped helps you pick the right one. They are sorted by pole configuration, contact state, and application.

By Pole Configuration (SPST, SPDT, DPST, DPDT)

Pole configuration shows how many circuits a relay can control. Common types include:

|

Relay Type |

Description |

Number of Pins |

|---|---|---|

|

SPST |

Single pole, single throw relay with one open terminal. |

4 |

|

SPDT |

Single pole, double throw relay with one open and one closed terminal. |

5 |

|

DPST |

Double pole, single throw relay with two outputs. |

5 |

|

DPDT |

Double pole, double throw relay with two open and two closed outputs. |

8 |

SPST relays are good for simple on/off tasks. DPDT relays handle more complex switching jobs. These configurations are often used in interposing relays, which connect control systems to high-power devices. They make systems easier to set up by matching signals to power needs.

By Contact State (Normally Open vs. Normally Closed)

Relays can also be grouped by their contact state. This shows if the relay's contacts are open or closed without power.

Normally Open (NO): The circuit stays open until the relay is powered. These are used in systems where "off" is the default, like lights or motors.

Normally Closed (NC): The circuit stays closed until the relay gets power. These are used in safety systems where "on" is the default, like emergency stops.

Interposing relays often use both NO and NC setups. For example, in factories, NC relays stop motors quickly during faults.

By Application (Automotive, Industrial, Home Automation)

Relays are also grouped by where they are used. Each area has special needs that decide the relay type:

Automotive: Car relays handle heat, shaking, and voltage changes. High-amp relays are common for headlights, fans, and starters.

Industrial: Factory relays control big machines like motors and pumps. Interposing relays connect low-power controls to high-power equipment.

Home Automation: Smart home relays manage lights, blinds, and thermostats. Time-delay relays help automate tasks like turning off lights later.

A study shows relay trends by region:

|

Region |

Key Insights |

|---|---|

|

Americas |

Growth from better power grids, electric cars, and factory automation. |

|

Europe, Middle East, and Africa |

Demand rises due to energy rules and renewable goals, focusing on digital relay tech. |

|

Asia-Pacific |

Fastest growth due to new factories and support for smart energy. |

In all areas, interposing relays improve system reliability. They help parts work together smoothly, making them very useful today.

Interposing Relay and Its Role in System Integration

An interposing relay works like a bridge between two systems. These systems may use different voltages or signals. The relay helps them work together smoothly. It is very important in complicated electrical setups.

What Does an Interposing Relay Do?

Think of an interposing relay as a helper. It takes signals from one system and changes them. This way, another system can understand and use the signals. For example, a low-power system might need to control a high-power motor. The relay makes this connection safe and easy.

Signal Matching: It adjusts signals to fit connected devices.

Isolation: It keeps sensitive parts safe from high-power circuits.

Amplification: It strengthens weak signals to control bigger loads.

Why Are Interposing Relays Important?

Interposing relays are key for making systems work together. Without them, devices might not connect properly. Here's why they are useful:

Improved Compatibility: They help systems with different electrical setups work together.

Enhanced Safety: They protect control circuits from power circuit risks.

Simplified Design: They reduce the need for extra wiring or parts.

Tip: Use an interposing relay when linking low-power controls to high-power machines. It makes the process easier and safer.

Applications of Interposing Relays

Interposing relays are used in many industries because they are flexible. Common uses include:

Industrial Automation: They connect controllers to heavy machines.

Building Management Systems: They link control panels to HVAC, lights, and elevators.

Power Distribution: They manage signals between control rooms and high-power equipment.

How to Choose the Right Interposing Relay

When picking an interposing relay, think about these points:

|

Factor |

Why It Matters |

|---|---|

|

Voltage Rating |

Makes sure the relay handles both systems' voltages. |

|

Current Capacity |

Ensures the relay can handle the load safely. |

|

Contact Configuration |

Matches the relay's switches to your system's needs. |

Choosing the right relay makes your system work better and last longer.

Did you know? Factories use interposing relays to protect controllers from power surges in motors.

Interposing relays make system integration easier. They help different parts work together without problems. This makes them very important in today's electrical systems.

Benefits of Plug-In Relays

Easy to Replace

Plug-in relays are simple to swap out. You don't need special tools or training to replace them. This makes fixing systems faster and keeps them running smoothly. Many industries like this because it saves money and time.

Main Benefits:

Quick replacement saves repair time.

Less downtime means fewer work interruptions.

Flexible mounting fits different setups easily.

Plug-in relays last a long time and work reliably. Their toughness makes them cheaper in the long run compared to other relays. Choosing plug-in relays gives you a mix of ease and dependability.

Works in Many Systems

Plug-in relays can be used in lots of places. They are helpful in cars, factories, and smart homes. Their flexibility makes them a favorite for engineers and technicians.

For example, in cars, they control headlights and cooling fans. In factories, they run big machines and motors. In smart homes, they manage lights and temperature settings. This wide use makes plug-in relays fit many industries.

Tip: Plug-in relays are a great choice for different jobs.

Better System Safety

Plug-in relays make electrical systems safer. They separate control circuits from high-power devices. This protects delicate parts from damage caused by power spikes.

Relays also stop overheating by controlling electricity flow. High-amp relays handle strong currents safely. Their sturdy design lowers the chance of fires or equipment breaking.

Why It's Important:

Shields control circuits from power surges.

Prevents overheating in systems with high currents.

Makes your setup more reliable overall.

Using plug-in relays keeps your system safe and efficient. Their safety features are key for modern electrical setups.

Cost-Effectiveness and Longevity

Plug-in relays are a smart way to save money. They are built to last and work well in many systems.

How Plug-In Relays Save Money

Plug-in relays help cut costs in different ways:

Lower Starting Costs: These relays cost less than many other types.

Easy Maintenance: Their design makes replacing them quick and cheap.

Energy Saving: Latching relays use less power, saving energy over time.

Tip: Pick relays with energy-saving features to lower your bills.

Made to Last

Plug-in relays are tough and built to handle wear. Strong materials like corrosion-proof contacts make them last longer.

Reliable Performance: They work well even in heat or shaking.

Less Downtime: Their durability keeps systems running without problems.

Comparing Costs and Lifespan

Here's how plug-in relays compare to other types:

|

Relay Type |

Starting Cost |

Repair Cost |

Lifespan |

|---|---|---|---|

|

Mechanical Relays |

Low |

Medium |

5–10 years |

|

Solid-State Relays |

High |

Low |

10–15 years |

|

Plug-In Relays |

Medium |

Low |

8–12 years |

Plug-in relays balance cost and lifespan, making them a great choice.

Why Are They Cost-Effective?

Their simple design makes them easy to install and replace. You don't need special tools, which saves time and money. Plus, they work in many systems, so you don't need different types.

Did you know? Using plug-in relays can cut maintenance costs by 20% each year.

Plug-in relays are affordable, durable, and reliable, making them a smart pick for your systems.

Plug-in relays are important in today's electrical systems. Knowing their types, like mechanical and solid-state, helps you pick the right one. Sorting relays by poles, contact state, and use makes them work better. Electromechanical relays are the most popular, making up 58% of sales.

Cars need the most relays, with 55% of the demand. The relay market is expected to grow to $20.48 billion by 2034. Picking the right relay improves safety, performance, and saves money. Choosing carefully ensures your system works well and lasts longer.

FAQ

What does a plug-in relay do?

A plug-in relay controls circuits by opening or closing connections. It works like a switch, helping devices run safely in cars, factories, and smart homes.

How are plug-in relays different from other relays?

Plug-in relays are simple to install and replace. Their design lets you swap them quickly without needing special tools. This makes them great for systems that need regular updates or repairs.

What should you check before picking a plug-in relay?

Look at the relay's voltage, current limit, and contact setup. These details help match the relay to your system, improving safety and performance.

Why are latching relays useful?

Latching relays save power by staying in position without constant electricity. They also stay cooler, lasting longer. This makes them perfect for battery-powered gadgets and energy-saving setups.

Which industries use plug-in relays the most?

Plug-in relays are key in cars, factories, and smart homes. They handle jobs like running motors, lights, and heavy equipment, keeping systems safe and working well.