The contact material of relay is crucial for ensuring good electrical connections. It prevents issues such as sticking, damage, or rust that can lead to problems. Selecting the appropriate contact material of relay enhances its performance and longevity. For example, tests indicate that hardened silver-palladium contacts wear 30% less after one million uses compared to standard silver contacts. Regulations like RoHS also advocate for the use of eco-friendly materials, such as silver-nickel blends, to improve strength and environmental sustainability.

Choosing the right contact material of relay ensures greater reliability and meets performance requirements.

Key Takeaways

-

Picking the right relay contact material is very important. It helps avoid problems like rust and sticking.

-

-

Silver mixes, like silver cadmium oxide, work well for high power. They are strong and carry electricity easily.

-

-

Gold contacts are great for low-power jobs. They send signals reliably and don't rust.

-

-

Things like humidity and chemicals can harm relay contacts. Use materials like palladium-copper alloys in tough conditions.

-

-

Checking and maintaining relay contacts often can make them last longer. This also stops expensive problems.

What Are Relay Contacts and Why Do They Matter?

Definition and Role of Relay Contacts

Relay contacts are parts inside a relay that join or break circuits. When the relay turns on, its contacts move to let electricity flow or stop. These contacts link the input and output circuits, making sure everything works smoothly. If relay contacts fail, circuits might stop working or damage connected devices.

Factors That Affect Relay Contact Performance

Many things affect how well relay contacts work over time. High electricity levels can make them overheat and wear out. Switching them on and off often causes stress and damage. Humid air or harmful chemicals can speed up wear and cause failure. Taking care of relays helps them last longer. Checking them often can catch problems early and keep them working well.

|

Factor |

Description |

|---|---|

|

Shows how long a relay works before it might fail. |

|

|

Environmental Conditions |

Heat and humidity can cause damage and lower reliability. |

|

Maintenance Practices |

Regular checks find problems early and help relays last longer. |

Importance of Choosing the Right Contact Material

Picking the right contact material is key for good performance. Different materials work better for certain jobs. For example, silver alloys fight rust and handle high electricity well. Gold-plated contacts are great for low-power signals. Using the wrong material can cause problems like rust, sticking, or fast wear. Choosing the right material helps the relay work better and last longer.

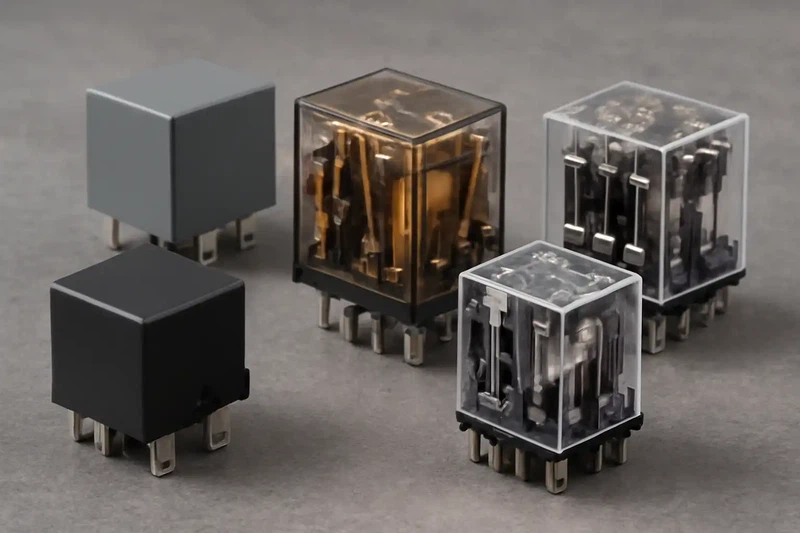

Types of Relay Contact Materials

Silver and Silver Alloys (e.g., Silver Cadmium Oxide, Silver Tin Oxide, Hard Silver)

Silver is a popular material for relay contacts. It allows electricity to flow easily, making it great for high current use. But pure silver can wear out or tarnish over time. To fix this, silver alloys are often chosen.

-

Silver Cadmium Oxide: This mix combines silver's ability to conduct electricity with cadmium oxide's strength against sparks. It works well for relays that switch often in high-power setups.

-

-

Silver Tin Oxide: Tin oxide makes the contact tougher and stops welding under heavy loads. This alloy is used in machines for factories.

-

-

Hard Silver: Hard silver is stronger than regular silver. It lasts longer and doesn't bend easily. It's good for relays with medium electrical loads.

-

Tip: For relays handling strong currents or tough conditions, silver alloys like silver cadmium oxide or silver tin oxide are reliable choices.

Gold and Gold-Plated Contacts

Gold is a top choice for relay contacts needing accuracy and dependability. It doesn't rust, making it perfect for low-power and signal tasks.

Gold-plated contacts are used in phones and delicate electronics. A thin gold layer stops rust, keeping performance steady. Gold contacts cost more but last longer and work better, making them worth the price.

-

Advantages:

-

-

Doesn't rust or corrode easily.

-

-

Works well in circuits with low power.

-

-

Great for relays used in sending signals.

-

-

Note: Gold contacts are best for places where even small rust could cause problems.

Tungsten and Tungsten Alloys

Tungsten is tough and works well in hot and high-voltage setups. It's hard and doesn't wear out quickly, making it good for relays in extreme conditions.

Tungsten alloys, like tungsten carbide, are used in relays handling heavy electricity. These materials resist sparks and damage, lasting a long time. But tungsten isn't great for low-power tasks since it doesn't conduct electricity as well as silver or gold.

-

Applications:

-

-

Relays in powerful factory machines. -

-

Relays in systems that spread electricity.

-

-

Tip: For relays in high-voltage setups, tungsten contacts are durable and dependable.

Palladium and Copper Alloys

Palladium and copper alloys are great for relay contacts. They are strong, conduct electricity well, and resist rust. These qualities make them dependable for long-term use. These alloys are often used where accuracy and stability are very important.

Palladium is special because it doesn't tarnish or wear easily. This helps relays work steadily over time. It is commonly used in car systems like spark plugs and sensors. Palladium handles heat and resists rust, making it perfect for tough jobs. Copper improves how well the alloy carries electricity, ensuring smooth current flow.

When palladium and copper are mixed, the alloy becomes both strong and conductive. This makes it ideal for relays in delicate electronics and factory machines. The alloy also resists rust, so it works well in harsh places like chemical plants or outdoors.

-

Key Benefits of Palladium and Copper Alloys:

-

-

Resist tarnish and rust very well. -

-

Carry electricity efficiently for smooth current flow.

-

-

Stay strong in heat and tough conditions.

-

-

-

-

Work well in both small and large power tasks.

-

-

Tip: For tough jobs, choose relays with palladium and copper alloy contacts. They are durable and reliable, even in hard conditions.

Applications of Relay Contact Materials

High-Power Applications (e.g., industrial machinery, power distribution)

Relay contacts are important for switching high-power loads. These materials are used in machines and systems that handle strong currents. Silver alloys and tungsten contacts work well in these setups. They resist damage from electrical arcs during switching.

For example, in factories, relays control motors or transformers. The contact material must handle heat and stay conductive under stress.

Tungsten contacts are tough and resist wear in these conditions. Picking the right material keeps relays working and avoids costly repairs.

Low-Power and Signal Applications (e.g., telecommunications, sensitive electronics)

Low-power tasks need precise and stable relay contacts. Gold or gold-plated contacts are common in phones and delicate electronics. They conduct electricity well and don't rust, even in small circuits.

For instance, a relay in a communication device uses gold contacts to send clear signals. Rust or tarnish could mess up the signal and cause problems. Gold stays steady over time, making it the best choice for low-power jobs.

Tip: Use gold or gold-plated contacts for devices needing clear signals.

Corrosive and Specialized Environments (e.g., chemical plants, outdoor installations)

Some places expose relays to tough conditions like chemicals or moisture. Contact materials must resist rust and keep working well. Palladium and copper alloys are great for these situations.

Imagine a relay in a chemical plant. Its contacts must survive exposure to harmful substances. Palladium doesn't tarnish, so the relay keeps working. Outdoor relays, like those in power grids, also benefit from these materials. They handle humidity and temperature changes,

staying reliable over time.

Note: For relays in harsh places, choose palladium-copper alloys for strength and reliability.

How to Choose the Right Relay Contact Material

Think About the Load Type (AC vs. DC, Current, Voltage)

The kind of load affects the choice of contact material. Loads can be resistive, like light bulbs, or inductive, like motors. Inductive loads are harder to turn off because they create extra energy. This energy can cause sparks that harm the relay and shorten its life.

AC and DC loads behave differently. DC voltage is easier to handle when opening contacts. But DC arcs last longer, so DC current ratings are usually lower than AC. For example:

|

Voltage Type |

Load Type |

Resistive Rating |

Inductive Rating |

|---|---|---|---|

|

110 VAC |

AC |

10 A |

7.5 A |

|

220 VAC |

AC |

7.5 A |

5 A |

|

30 VDC |

DC |

10 A |

5 A |

Pick a contact material based on your current and voltage needs. For high-current AC loads, silver alloys like silver cadmium oxide work well. They resist damage and handle sparks. For low-current DC loads, gold or gold-plated contacts are better. They prevent rust and ensure steady performance.

Tip: Match the contact material to the load type to avoid relay problems.

Check Environmental Conditions (Humidity, Corrosion)

Conditions like humidity, heat, and chemicals can affect relay performance. High humidity can cause rust, making the relay less effective. Chemicals or outdoor weather can also wear out the contacts faster.

For wet or harsh environments, palladium-copper alloys are a good choice. Palladium resists rust and lasts a long time. For outdoor setups, like power systems, tungsten contacts are strong. They handle heat and sparks without breaking down.

In clean places, gold-plated contacts are a great option. They work well for low-power tasks where rust isn't a big issue.

Note: Think about the environment to pick a material that will last.

Match Material to Your Application

Each contact material has special features for different jobs. Choosing the right one helps the relay work better and last longer.

-

High-Power Applications: For factory machines or power systems, use silver tin oxide or tungsten. These materials handle strong currents and stop sparks.

-

-

Low-Power Applications: For phones or small electronics, gold or gold-plated contacts are best. They stay clean and keep signals clear.

-

-

Specialized Environments: In chemical plants or outdoors, palladium-copper alloys are strong and resist rust.

-

Think about what your relay needs to do. For example, a factory relay might need tungsten to handle high voltage. A phone relay would need gold-plated contacts for clear signals.

Tip: Choose materials that fit your relay's job to make it last longer.

Relay contact materials are important for making relays work well. Different materials have special uses for different tasks. For instance, copper helps electricity flow better, and silver lowers voltage loss, making relays last longer. Gold is great for small currents, while tungsten works well in tough, high-power situations.

|

Material Type |

Benefits |

How It Helps Performance |

|---|---|---|

|

Copper |

Lets electricity flow easily |

Lowers resistance, making it more efficient |

|

Silver |

Conducts electricity better than copper |

Reduces voltage loss, helping relays last |

|

Gold |

Works well with small currents |

Makes relays more reliable for tiny tasks |

|

Tungsten |

Handles strong currents and heat |

Keeps working in hard, high-power setups |

Picking the right material for your relay's job and surroundings helps it last longer and work its best.

FAQ

What happens if you choose the wrong relay contact material?

Picking the wrong material can cause overheating or rust. Contacts might stick together, shortening the relay's life. Devices could stop working. For example, gold contacts wear out fast in high-power setups.

Tip: Always pick a contact material that fits your power and environment needs.

Why are silver alloys so common in relays?

Silver alloys are strong and let electricity flow easily. They handle high currents and don't stick during switching. For example, silver tin oxide works well in factory machines by stopping arc damage.

Note: Silver alloys are flexible and great for most high-power uses.

Are gold contacts worth the extra cost?

Gold contacts are great for low-power tasks or signals. They don't rust and work well in delicate electronics. Even though they cost more, they last longer and are reliable for devices like phones.

Can environmental conditions damage relay contacts?

Yes, things like moisture, heat, or chemicals can harm contacts. In tough places, palladium-copper alloys or tungsten work better. These materials fight rust and stay strong in hard conditions.

How do you know when to replace relay contacts?

If contacts overheat, resist electricity, or act unevenly, they're worn out. Regular checks can find these problems early. Replacing them on time stops bigger issues.

Tip: Check relays often to make them last longer and avoid breakdowns.