You need specific features to make a relay handle two circuits safely. A DPDT design lets you switch each circuit without mixing signals. Electrical isolation keeps current from jumping between circuits. Strong contacts stop overheating and wear. These features protect your devices and help a relay handle two circuits with less risk. You get safer, more reliable control every time.

Key Takeaways

DPDT relays let you control two separate circuits safely without mixing signals.

Strong electrical isolation inside relays keeps circuits separate and protects devices.

Choosing the right contact material helps prevent relay wear and overheating.

Always check contact ratings to match your relay with your load's current and voltage.

Proper wiring and following pin numbering standards prevent mistakes and keep systems safe.

Fail-safe features and overload protection help avoid damage and keep circuits reliable.

Selecting relays designed for your environment and load type extends relay life.

Testing your relay setup before use ensures safe and dependable operation.

Key Features

DPDT Design

A DPDT (Double Pole Double Throw) relay gives you the ability to control two separate circuits at the same time. Each pole acts like a switch for one circuit, so you can turn both on or off together or in different ways. This design keeps the circuits from mixing signals, which is important for safety. You often see DPDT relays in places where you need to switch two loads, like in X-ray machines or industrial controls.

A DPDT relay uses strong mechanical parts to make sure both circuits stay separate. Forcibly guided contacts link the normally open (NO) and normally closed (NC) contacts. This means both contacts cannot close at the same time. If a contact welds shut, the relay can detect the problem and trigger a fail-safe response. These features follow strict IEC standards, which require the relay to work safely for at least 10 million cycles. This makes the DPDT design reliable for long-term use.

|

Feature |

Description |

|---|---|

|

Relay Type |

DPDT (Double Pole Double Throw) |

|

Application |

X-Ray systems, dual-circuit control |

|

Contact Material |

Silver cadmium oxide |

|

Environmental Protection |

Dust cover |

|

Mechanical Life Expectancy |

10 million operations |

|

Initial Contact Resistance |

50 milliohms |

|

Terminal Type |

250° combination quick connect/solder terminals |

|

Design Focus |

High performance, reliability, and durability |

Electrical Isolation

Electrical isolation is what keeps the two circuits from interfering with each other. When you use a relay to handle two circuits, you want to make sure that current from one side does not jump to the other. The relay coil and contacts stay separated by insulation and air gaps. This setup protects your devices and keeps you safe.

Engineers test relays for insulation resistance, contact resistance, and timing. These tests make sure the relay can keep the circuits apart, even after many uses. Organizations like NETA set rules for how often you should check these features. Good electrical isolation means your relay will keep working, even in tough conditions.

Tip: Always check the isolation voltage rating before you use a relay. This number tells you how much voltage the relay can handle between its coil and contacts without breaking down.

Contact Materials

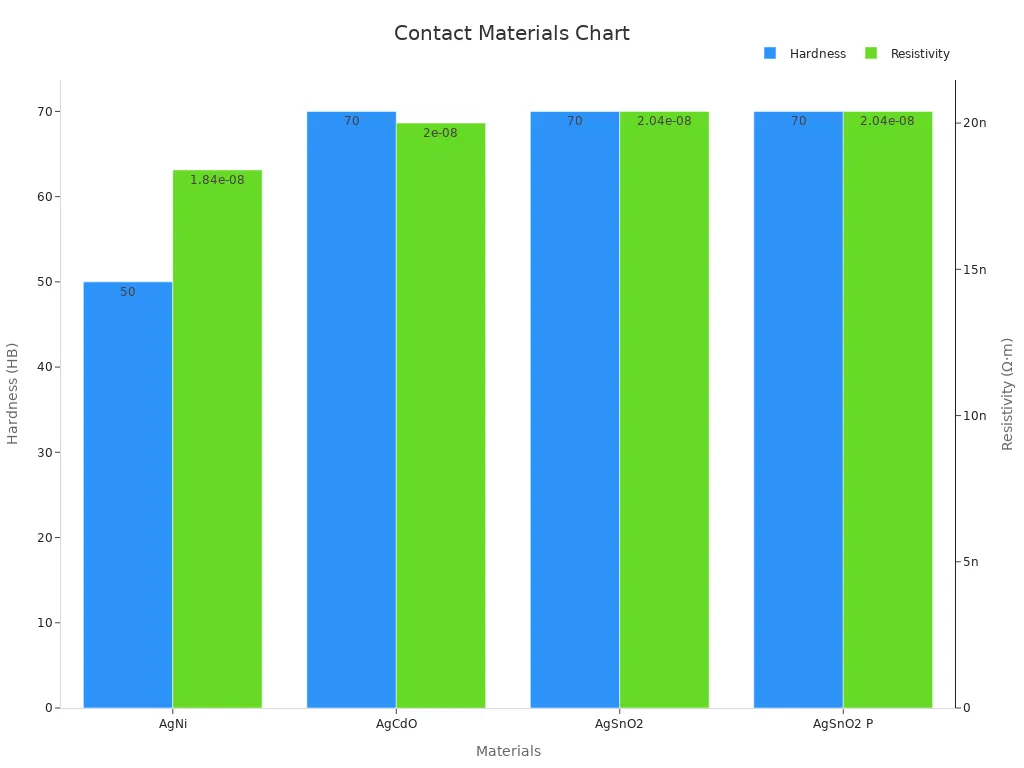

The material used for relay contacts affects how well the relay works and how long it lasts. Different metals have different strengths. For example, silver nickel (AgNi), silver cadmium oxide (AgCdO), and silver tin oxide (AgSnO₂) are common choices. Each one has its own benefits for durability, resistance to welding, and ability to handle high currents.

AgSnO₂ stands out for its low welding and erosion tendency, especially during short arcs. AgCdO has a higher welding tendency but lower contact resistance. AgNi offers moderate welding resistance and less material transfer. The right contact material helps your relay handle two circuits safely by reducing the risk of overheating and wear.

|

Contact Material |

Composition |

Density (kg/m³) |

Hardness (HB) |

Thermal Conductivity (W/K/m) |

Electrical Resistivity (Ω·m) |

Durability and Resistance Characteristics |

|---|---|---|---|---|---|---|

|

AgNi |

90% Ag + 10% Ni |

10,300 |

50 |

350 |

1.84 × 10⁻⁸ |

Moderate welding resistance; similar welding and tearing resistance to AgSnO2; lower material transfer than AgCdO |

|

AgCdO |

90% Ag + 10% CdO |

10,200 |

70 |

307 |

2.00 × 10⁻⁸ |

Higher welding tendency; higher material transfer; lower contact resistance; slightly higher erosion |

|

AgSnO2 |

90% Ag + 10% SnO₂ (bimetal rivet) |

9,900 |

70 |

307 |

2.04 × 10⁻⁸ |

Best performance under short arcs; low welding and erosion tendency for short arcs; stronger welds but lower welding occurrence; good durability under fault currents |

|

AgSnO2 P |

Variation of AgSnO2 (single metal rivet) |

9,900 |

70 |

307 |

2.04 × 10⁻⁸ |

Designed for higher inrush currents; similar beneficial properties as AgSnO2 |

Choosing the right contact material helps you get the most out of your relay. It keeps your circuits safe and extends the relay's service life.

Contact Ratings

Contact ratings tell you how much current and voltage a relay can safely switch. You need to check these numbers before you use a relay to handle two circuits. If you choose a relay with the wrong contact ratings, you risk overheating, contact welding, or even fire. Manufacturers test relays in many ways to make sure the contact ratings match real-world needs.

You should look for these key points when checking contact ratings:

Current and Voltage Limits: Each relay lists the maximum current (in amps) and voltage (in volts) it can handle. For example, some relays can switch up to 20A at 250VAC. This sets the safe limit for your circuits.

Switching Cycles: Relays must last for thousands of operations. Many datasheets promise at least 100,000 cycles at full load. This tells you the relay will keep working over time.

Load Type: Not all loads are the same. Motors and lights draw more current when they start. Relays must handle these inrush currents without damage.

Thermal Performance: Relays heat up during use. Manufacturers measure the temperature of the relay case and terminals to make sure it stays safe.

Contact Resistance: Over time, contacts can wear out. Engineers measure resistance to check for wear and make sure the relay still works well.

Here is a table that shows the main tests used to check contact ratings:

|

Test Aspect |

Description |

Importance for Validation |

|---|---|---|

|

Resistive Load Tests |

Standard life tests use resistive loads without inrush or counter currents. |

Establish baseline contact rating and endurance. |

|

Inductive Load Tests |

Tests with inductive loads (motors, solenoids) that generate counter voltages and arc discharges. |

Validate relay's ability to handle arc and inrush currents. |

|

Capacitive Load Tests |

Tests with capacitive loads producing inrush currents 20-40 times steady current. |

Ensure relay contacts withstand high surge currents. |

|

Switching Cycles |

Extended lifetime tests measuring number of switching operations at rated current (e.g., 20A). |

Confirm relay durability over expected operational life. |

|

Contact Resistance |

Measurement of contact resistance under load to monitor degradation over time. |

Detect contact wear and validate contact integrity. |

|

Overtemperature Tests |

Monitoring relay temperature during operation under rated load. |

Ensure thermal limits are not exceeded, preventing failure. |

When you want a relay handle two circuits, you must match the contact ratings to your loads. Always check the datasheet for the right numbers. If you use a relay with higher ratings than your load, you add a layer of safety. If you use a relay with lower ratings, you risk failure.

Note: Never guess the contact ratings. Always use the numbers from the manufacturer. This keeps your circuits safe and your relay working for a long time.

Relay Handle Two Circuits

How Relays Separate Circuits

A relay can keep two circuits completely separate. When you use a DPDT or multi-pole relay, each pole acts as an independent switch. You control two different electrical paths at the same time, but the current from one circuit never touches the other. This separation protects your devices from cross-talk or accidental short circuits.

You find this feature important when you want a relay handle two circuits that have different voltages or types of loads. For example, you might want to switch a high-voltage motor and a low-voltage signal light with the same relay. The relay keeps the circuits apart using strong insulation and air gaps inside the device. This design prevents electrical faults and keeps your system safe.

Switching Mechanism

The switching mechanism inside a relay uses a coil, an armature, and contacts. When you send power to the coil, it creates a magnetic field. This field moves the armature, which then pushes the contacts to open or close the circuits. In a DPDT relay, you get two sets of contacts moving together, so you can switch two circuits at once.

Modern relay switching mechanisms show reliable performance in real-world tests. For example, in dual power switching boxes, the relay can switch between primary and backup power in about 3 to 5 seconds. Voltage sensors and control circuits work with the relay to detect when the voltage drops below a safe level. The relay then switches automatically, keeping your equipment running with minimal

interruption. Some advanced relays add a delay feature. This delay stops the relay from switching back too quickly during voltage changes, which helps your system stay stable and reliable.

Tip: Always choose a relay with a proven switching mechanism. Reliable switching means your relay handle two circuits safely, even during power changes or heavy use.

Pin Numbering and Standards

Pin numbering and wiring standards help you connect relays correctly. Each pin on a relay has a specific function, such as coil input, common, normally open (NO), or normally closed (NC). International standards make sure that pin layouts stay the same across different brands and models.

IEC standards like IEC 60309, IEC 60828, IEC 60204, and IEC 60228 set the rules for connectors, wiring, and safety. These standards make sure you get the same pin numbering and wiring practices in every country.

EASA Easy Access Rules and FAA Advisory Circulars give extra guidelines for wiring in airplanes and other critical systems. They cover things like connector seals, wire routing, and how to prevent corrosion or overheating.

These standards help you avoid mistakes, such as bridging two circuits by accident. They also make it easier to replace or upgrade relays without changing your wiring.

You should always check the relay datasheet for the correct pin numbers. Following these standards means your relay handle two circuits safely and reliably, no matter where you use it.

Relay Types

DPDT Relays

A DPDT relay stands for Double Pole Double Throw relay. You use this type when you want to control two separate circuits with one relay. Each pole acts as a switch for one circuit. You get two sets of contacts, so you can open or close both circuits at the same time. This design keeps the circuits isolated from each other.

What makes DPDT relays special is their flexibility. You can use them to reverse the direction of a motor, switch between two power sources, or control two different devices at once. The contacts in a DPDT relay stay strong and reliable, even after thousands of cycles. You often find these relays in industrial machines, home automation, and even in some audio equipment.

Tip: When you need to switch two circuits without mixing signals, a DPDT relay gives you a safe and simple solution.

Multi-Pole Relays

Multi-pole relays take the idea of DPDT relays further. You get more than two poles, so you can control three, four, or even more circuits at once. Each pole works as an independent switch. You can use multi-pole relays when you need to manage several circuits with one control signal.

What sets multi-pole relays apart is their ability to handle complex switching tasks. You might use them in large control panels, elevator systems, or advanced lighting setups. The design of these relays keeps each circuit separate. You do not have to worry about one circuit affecting another.

Here is what you get with multi-pole relays:

More control: Switch several circuits at once.

Better safety: Each circuit stays isolated.

Flexible wiring: Use one relay for many tasks.

Multi-pole relays help you save space and reduce wiring mistakes. You can trust them for safe and reliable operation in demanding environments.

ISO Mini Relays

ISO mini relays are compact relays that follow international standards for size and pin layout. You often see these relays in automotive and industrial applications. They fit into standard relay sockets, so you can replace or upgrade them easily.

What makes ISO mini relays useful is their small size and high performance. You get a relay that can handle high currents in a tight space. The standardized design means you do not have to guess about wiring or compatibility.

|

Feature |

What It Means for You |

|---|---|

|

Compact Size |

Fits in small spaces |

|

Standardized Pins |

Easy to install and replace |

|

High Current Rating |

Handles demanding loads |

You can use ISO mini relays to control headlights, fuel pumps, or fans in vehicles. You also find them in control panels for machines. These relays give you safe, reliable switching for two circuits or more, all in a small package.

Solid-State Relays

Solid-state relays (SSRs) use electronic components instead of moving parts to switch circuits. You get fast, silent switching and long life because there are no contacts to wear out. When you want to control two circuits safely, SSRs offer some unique features.

What makes solid-state relays safe for dual-circuit control?

Electrical Isolation:

SSRs use optical isolation. An LED inside the relay shines on a sensor, which triggers the switching. This keeps the input side completely separate from the output side. You protect your control circuit from high voltages or spikes in the load circuit.

No Moving Parts:

You do not have to worry about contact bounce or arcing. SSRs switch silently and instantly. This reduces the risk of sparks, which can cause fires or damage sensitive equipment.

Consistent Performance:

SSRs handle thousands of cycles without changing how they work. You get the same switching speed and reliability every time.

Built-in Protection:

Many SSRs include features like overvoltage protection, short-circuit protection, and thermal shutdown. These features help you avoid damage if something goes wrong in your circuits.

Note: You should always check the datasheet for the SSR's isolation voltage and maximum load ratings. Using an SSR outside its ratings can cause failure.

|

Feature |

What It Means for You |

|---|---|

|

Optical Isolation |

Keeps control and load circuits separate |

|

Fast Switching |

No delay or noise during operation |

|

Long Life |

No contacts to wear out |

|

Overload Protection |

Prevents damage from high current or voltage |

|

Compact Size |

Fits in tight spaces in control panels |

What should you look for when using SSRs for two circuits?

Choose a dual-channel SSR:

Some SSRs have two independent channels in one package. You can control two circuits with one device, and each channel stays isolated.

Check the load type:

SSRs work best with resistive loads like heaters or lamps. Some models can handle motors or inductive loads, but you need to check the specs.

Follow wiring best practices:

Use proper wire sizes and secure connections. Make sure you do not cross the input and output sides.

Watch for heat:

SSRs can get hot during use. You may need a heat sink to keep the relay cool and safe.

Tip: If you need silent, fast, and reliable switching for two circuits, solid-state relays give you a modern solution. Always match the SSR to your load and follow safety guidelines for the best results.

Internal Structure

Coil and Armature

Inside every relay, you find a coil and an armature. The coil wraps around an iron core. When you send electricity through the coil, it creates a magnetic field. This field pulls the armature, which is a movable metal piece. The armature moves to open or close the relay's contacts. A reset spring connects to the armature and pushes it back when the coil turns off. This simple design lets you control circuits with just a small electrical signal.

Here is a table that shows the main parts inside a relay:

|

Part |

What It Does |

|---|---|

|

Coil |

Creates a magnetic field when powered |

|

Iron Core |

Focuses the magnetic field |

|

Armature |

Moves when the coil is energized |

|

Reset Spring |

Returns the armature to its original position |

|

Moving Contact |

Connects or disconnects from fixed contacts |

|

Fixed Contact |

Stays in place; can be Normally Open (NO) or Normally Closed (NC) |

|

Relay Types |

Can be Electromechanical (with moving parts) or Solid-State (no moving parts) |

Figures in technical diagrams often show these parts clearly. You can see how the coil, armature, and contacts fit together in relay structure diagrams.

Contact Arrangement

The contact arrangement inside a relay decides how you can control your circuits. You usually see contacts labeled as Normally Open (NO), Normally Closed (NC), or Form C (which combines both). When the relay is off, the NO contact stays open and the NC contact stays closed. When you power the coil, the armature moves, switching the contacts. This setup lets you choose if you want a circuit to turn on or off when the relay activates.

Engineering studies show that the way contacts are arranged affects how much current the relay can handle and how reliable it is. For example, Form C contacts use one actuator to control both NO and NC contacts. This design gives you efficient switching and clear logic states. You often use NO contacts for alarms or devices that should only run when needed. NC contacts work well for safety circuits that must stay on unless something goes wrong.

Switching Action

The switching action in a relay happens when the coil pulls the armature, causing the moving contact to touch or leave the fixed contacts. This action lets you open or close circuits quickly and safely. The design of the contacts and the speed of the armature movement help prevent sparks and reduce wear.

Studies explain that the type and arrangement of contacts, such as NO, NC, or timing contacts, change how the relay switches. Timing relays can delay the switching, which helps in control systems. The materials and ratings of the contacts also matter. Good contact design reduces arcing and makes the relay last longer. You get reliable switching every time, which is important for safety and performance.

Tip: Always check the relay's datasheet for details about its internal structure. Knowing what is inside helps you pick the right relay for your project.

Safety Features

Isolation Techniques

Isolation techniques keep you safe when you use a relay handle two circuits. The relay separates the control side from the load side. This means that high voltage or current on one side cannot reach the other side. You often see insulation barriers and air gaps inside the relay.

These features stop electricity from jumping between circuits.

Protection relays monitor voltage, current, and other electrical values. They can spot problems like short circuits or overloads right away. When a fault happens, the relay acts quickly to isolate the problem. This fast action keeps your equipment safe and prevents damage.

Laboratory tests show that relays can detect and isolate faults within milliseconds. This speed helps you avoid bigger problems in your system.

Note: Always check the isolation voltage rating before you choose a relay. This number tells you how much voltage the relay can safely separate.

Fail-Safe Mechanisms

Fail-safe mechanisms make sure your system stays safe, even if something goes wrong. Many relays use special contacts that cannot close at the same time. If a contact welds shut, the relay can detect this and trigger a backup response. Some relays use communication protocols like GOOSE messaging. These protocols let relays talk to each other and coordinate their actions.

When a relay finds a fault, it can trip a breaker or switch off a circuit. This selective tripping means only the problem area shuts down. Your other circuits keep working. Relays also record events and performance data. You can use this information to check how well your safety features work and make improvements if needed.

Relays with fail-safe designs help you avoid accidents.

Event recording lets you review what happened during a fault.

Communication between relays supports fast and reliable protection.

Overload Protection

Overload protection stops your relay and circuits from getting too hot or damaged. Relays use special curves, called inverse definite minimum time (IDMT) curves. These curves make the relay trip faster when the current is higher. This adaptive response protects your devices from harm.

You can see overload protection in action during real-time tests. Hardware-in-the-loop testing checks if the relay settings work as planned. The relay must trip at the right time to prevent overheating. Monitoring and recording features let you track how the relay responds to overloads. You can adjust settings to match your system's needs.

|

Overload Protection Feature |

What It Does |

|---|---|

|

IDMT Curves |

Faster trip at higher faults |

|

Real-Time Testing |

Confirms correct settings |

|

Event Monitoring |

Tracks relay performance |

When you use a relay handle two circuits, overload protection keeps both circuits safe. You get peace of mind knowing your system can handle unexpected surges or faults.

Selection and Wiring

Choosing the Right Relay

You need to select a relay that matches your application. The right relay keeps your circuits safe and working for a long time. When you control two circuits, you must look at several important features.

Pick a relay with a surge current rating higher than the highest inrush current your load will draw. This helps the relay last longer and prevents early failure.

Make sure the relay's voltage rating is equal to or greater than the voltage in your circuit. Check both the coil and contact ratings.

Think about where you will use the relay. High temperatures, humidity, or vibration can affect how well it works. Choose a relay built for your environment.

Look for strong isolation between the control and load sides. Good insulation and high dielectric strength protect your sensitive devices.

For dual-circuit control, select a relay with multiple contacts. This lets you manage two circuits at once without mixing signals.

These features follow industry standards for safety and reliability. You can trust your relay to perform well if you match these criteria.

Tip: Always check the datasheet for surge, voltage, and environmental ratings before you buy a relay.

Wiring Best Practices

Wiring your relay the right way helps you avoid mistakes and keeps your system safe. Neat and organized wiring makes troubleshooting easier and reduces the risk of errors.

Run wires in straight horizontal and vertical lines. This keeps your wiring neat and helps you spot problems quickly.

Keep communication wires away from high-power wires. This reduces electromagnetic interference and keeps your signals clean.

Use wire ducts or trays to organize your wires. This prevents tangling and makes your panel look professional.

Cross wires at 90-degree angles if you cannot separate them. This simple trick cuts down on interference.

Ground your system with a dedicated busbar. Good grounding lowers electrical noise and improves reliability.

Avoid ground loops. These can cause strange behavior in your circuits.

Choose the right wiring method for your devices. Sinking and sourcing methods affect how signals flow.

Select wire sizes that match your load. Follow standards like NEC or NFPA 79 to prevent overheating.

Use ferrules on stranded wires. Ferrules make connections stronger and stop wires from fraying.

Label every wire and use color codes. This makes repairs and upgrades much easier.

Test your wiring before you power up. Check for continuity, insulation, and pull strength to catch mistakes early.

Note: Careful wiring and testing help you avoid costly errors and keep your circuits running smoothly.

Load Matching

You must match your relay to the load it will control. This means checking the current and voltage your devices need. If your relay cannot handle the load, it may overheat or fail.

|

Load Type |

What to Check |

Why It Matters |

|---|---|---|

|

Resistive |

Steady current and voltage |

Prevents overheating |

|

Inductive |

Inrush current and spikes |

Avoids contact welding/arcing |

|

Capacitive |

High surge at switch-on |

Protects relay from damage |

Always choose a relay with ratings higher than your load. This gives you a safety margin and helps your relay last longer. Matching your relay to your load keeps your circuits safe and your system reliable.

Common Mistakes

When you work with relays to control two circuits, you can run into several common mistakes. Knowing what these mistakes are helps you avoid problems and keeps your circuits safe.

1. Choosing the Wrong Relay Type

You might pick a relay that cannot handle two circuits. For example, you may use a single-pole relay instead of a DPDT or multi-pole relay. This mistake means you cannot keep your circuits separate. Always check what type of relay you need before you buy.

2. Ignoring Contact Ratings

Some people use relays with contact ratings that are too low for their loads. This can cause overheating, contact welding, or even fire. You must match the relay's ratings to your circuit's voltage and current.

3. Poor Wiring Practices

Messy or incorrect wiring leads to short circuits, cross-talk, or unreliable operation. You might connect the wrong pins or mix up the NO and NC contacts. Always follow wiring diagrams and label your wires.

4. Skipping Isolation Checks

You may forget to check if the relay provides enough electrical isolation between circuits. Without proper isolation, high voltage can jump to the control side. This puts your devices and safety at risk.

5. Overlooking Load Type

You might not consider if your load is resistive, inductive, or capacitive. Each type affects how the relay works. For example, inductive loads like motors create voltage spikes that can damage contacts.

6. Not Testing After Installation

Some people skip testing after wiring the relay. This mistake can hide wiring errors or faulty relays. Always test for continuity and correct operation before you power up your system.

7. Forgetting About Environmental Factors

You may install a relay in a place with too much heat, moisture, or vibration. These conditions can shorten the relay's life or cause it to fail.

Tip: Make a checklist of what to review before you finish your relay project. This helps you catch mistakes early.

Here is a table that shows what mistakes to watch for and what problems they can cause:

|

Mistake |

What Can Happen |

|---|---|

|

Wrong relay type |

Circuits not isolated |

|

Low contact ratings |

Overheating, fire risk |

|

Messy wiring |

Short circuits, failures |

|

No isolation check |

Shock hazard, device damage |

|

Ignoring load type |

Contact wear, relay failure |

|

No testing |

Hidden faults, unsafe system |

|

Bad environment |

Early relay failure |

Knowing what mistakes to avoid helps you build safer and more reliable relay circuits. Always double-check your choices and wiring before you power up.

Applications

Industrial Use

You see relays used everywhere in modern factories and process plants. These devices help you control two circuits safely, which is important for keeping machines and workers protected. In industrial settings, relays let you start and stop motors, switch power sources, and manage safety systems with confidence.

Relays work well in manufacturing because they handle high currents and provide strong electrical isolation. You can use them to control heavy machines, conveyor belts, and even renewable energy systems. Their design keeps control signals and power lines separate, which helps prevent short circuits and overloads.

Here are some reasons why relays play a key role in industrial automation:

Electromechanical relays give you reliable and cost-effective control for power distribution, motor control, and safety systems.

Power relays handle large currents, which is essential for running big machines and switching heavy loads.

ON-delay relays help you sequence machines and prevent short circuits by delaying when equipment turns on.

Slim interface relays save space in control panels and provide strong isolation between control and load sides.

Modern relays often work with automation systems like PLCs and SCADA, making it easy for you to monitor and control processes.

High-temperature tolerant relays reduce failure rates and lower maintenance costs, even in tough environments.

Modular and plug-in relay designs let you replace parts quickly and scale your system as your needs grow.

IoT-enabled relays allow you to monitor equipment remotely and detect faults fast, which improves safety and uptime.

The global relay market keeps growing because industries need more automation and safer systems. In the United States, relays support 77% of the North American market, driven by demand from automotive, aerospace, and industrial automation. You also see growth in renewable energy and smart grid projects, which rely on relays for reliable switching.

Tip: When you choose relays for industrial use, look for features like high current ratings, strong isolation, and compatibility with your automation systems. These features help you build safer and more efficient factories.

Relays help you improve energy efficiency and keep your operations running smoothly. Their ability to control two circuits safely makes them a smart choice for any industrial application.

DIY Projects

You can use relays in many DIY projects to control two circuits safely. Relays give you a simple way to switch devices on and off with a small signal. You do not need to handle high voltage directly. This makes your projects safer and more reliable.

What makes relays useful for DIY projects?

Electrical Isolation: Relays keep your control circuit separate from your load circuit. You can use a low-voltage microcontroller to control a high-voltage device without risk.

Dual-Circuit Control: With a DPDT relay, you can switch two circuits at once. You can turn on a fan and a light together or switch between two power sources.

Easy Integration: Relays work with many controllers like Arduino, Raspberry Pi, or simple switches. You can add them to your project with basic wiring skills.

Wide Compatibility: You can use relays with AC or DC loads. This gives you flexibility for different devices.

Tip: Always choose a relay with contact ratings higher than your load. This helps prevent overheating and extends the life of your project.

What types of DIY projects use relays?

Home automation systems (control lights, fans, or appliances)

Remote-controlled garage doors

Model train layouts (switch tracks or signals)

Solar power switching (change between grid and solar)

Security alarms (activate sirens or lights)

Robotics (control motors or actuators)

Here is a table showing what features you should look for in a relay for DIY projects:

|

Feature |

What It Does for You |

|---|---|

|

DPDT or Multi-Pole |

Lets you control two circuits safely |

|

High Isolation |

Protects your controller |

|

Clear Pin Markings |

Makes wiring easier |

|

Snap-In Mounting |

Speeds up installation |

|

LED Indicator |

Shows relay status at a glance |

You can use relays to make your projects smarter and safer. For example, you can build a smart lamp that turns on when it gets dark and also powers a fan. You can use a relay to keep the circuits separate and avoid electrical hazards.

Note: Always follow safety rules when working with electricity. Double-check your wiring and test your relay before using your project.

You can find relay modules made for DIY use. These modules often include screw terminals, indicator LEDs, and protection diodes. You can connect them to your controller with just a few wires.

If you want to experiment, try this simple code for Arduino to control a relay:

int relayPin = 7; void setup() { pinMode(relayPin, OUTPUT); } void loop() { digitalWrite(relayPin, HIGH); // Turns relay ON delay(1000); digitalWrite(relayPin, LOW); // Turns relay OFF delay(1000); }

Relays open up many possibilities for your DIY projects. You can control two circuits safely and add new features to your creations. Always pick the right relay and follow best practices for safe and reliable results.

You now know what features let a relay control two circuits safely. Look for strong electrical isolation, the right contact materials, and correct ratings. Always choose the right relay for your job and follow safe wiring practices. Test your setup before use.

Safety and reliability should guide every project you build.

If you want to learn more, check out guides on advanced relay wiring and troubleshooting.

FAQ

What does DPDT mean in a relay?

DPDT stands for Double Pole Double Throw. You get two separate switches in one relay. Each switch controls its own circuit. This design lets you control two circuits at the same time without mixing signals.

What makes a relay safe for controlling two circuits?

You need strong electrical isolation, robust contact materials, and correct contact ratings. These features keep your circuits separate and prevent electrical faults. You protect your devices and ensure reliable operation.

What happens if you use the wrong contact rating?

If you use a relay with a low contact rating, you risk overheating, contact welding, or even fire. Always check the relay's datasheet. Pick a relay with ratings higher than your load.

What is electrical isolation in a relay?

Electrical isolation means the relay keeps the control side and load side separate. You prevent current from jumping between circuits. This protects your devices and keeps you safe.

What types of relays can control two circuits?

You can use DPDT relays, multi-pole relays, and some solid-state relays. Each type lets you switch two circuits independently. Always check the relay's specifications before use.

What should you check before wiring a relay?

You should check the pin numbering, contact ratings, and wiring diagram. Label your wires and test for continuity. This helps you avoid mistakes and keeps your circuits safe.

What is the best contact material for relays?

Silver tin oxide (AgSnO₂) works well for most loads. You get low welding and good durability. Always match the contact material to your application for the best results.

What mistakes should you avoid when using relays?

You should avoid using the wrong relay type, ignoring contact ratings, and poor wiring. Always test your setup before use. Careful planning keeps your circuits safe and reliable.