A solid-state relay is made of solid-state relay components featuring special materials and electronic parts. Inside, engineers use silicon and gallium arsenide as semiconductors. The device includes FETs, thyristors, opto-couplers, LEDs, and resistors. Plastics and metals form the external and internal frame. Thermal interface materials assist in dissipating heat. All these parts work together seamlessly without any moving pieces.

Key Takeaways

- Solid-state relays use materials like silicon, gallium arsenide, plastics, and metals. These materials help the relay work without moving parts. This makes the relay last longer. It can also handle tough places better.

- Important parts like LEDs, resistors, opto-couplers, FETs, and thyristors are inside the relay. These parts help control electricity safely. They also make the relay work fast.

- Thermal interface materials and snubber circuits protect the relay. They manage heat and stop damage from voltage spikes.

- Strong plastic and metal cases keep the relay safe. They protect it from dust, water, shocks, and vibrations. This helps the relay work well in hard places.

- Solid-state relays switch faster than mechanical relays. They last much longer. They work quietly and do not wear out fast. This is because they have no moving parts.

Made of Solid-State Relay

Solid-state relays have special materials and parts inside. These parts work together to control electricity. There are no moving pieces in these relays. This makes them last longer and work better. The main materials are semiconductors, plastics, metals, and thermal interface materials. Each one has a job inside the relay.

Semiconductor Materials

Semiconductors are the most important part of a solid-state relay. Engineers pick silicon and gallium arsenide for these parts. These materials help the relay switch signals fast and easily. Silicon is used a lot because it can handle high power. Gallium arsenide is good for fast or high-frequency jobs. Solid-state relays use field-effect transistors (FETs) and thyristors. These parts control how electricity moves.

They take the place of moving contacts in old relays. Because of this, solid-state relays last longer than mechanical ones.

Note: Solid-state relays do not have moving parts. This means they do not wear out quickly. They also work well in tough places.

The table below shows how electromechanical relays and solid-state relays are different. It explains how the materials and design change how they work:

| Characteristic | Electromechanical Relay (EMR) | Solid State Relay (SSR) |

|---|---|---|

| Operate and Release Time | 5 to 20 milliseconds | 10 to 25 milliseconds |

| Input to Output Isolation | 4 kV | Greater than 4 kV |

| Sensitivity to Corrosion | Yes | No |

| Sensitivity to Shock/Vibration | Yes | No |

| Cost per Pole | Best | Fair |

| Input TTL & CMOS Compatibility | Fair | Best |

This table shows that solid-state relay materials help stop corrosion and vibration. The relay also keeps input and output separate for safety.

Plastics and Metals

Plastics and metals make the outside and inside of a solid-state relay. The outside shell is usually strong plastic. This plastic keeps the inside safe from dust and water. Inside, metals like copper and aluminum move electricity. These metals also help get rid of heat.

Thermal interface materials fill spaces between hot parts and heat sinks. These materials move heat away from important parts. This keeps the relay cool and safe. The solid-state relay uses these materials to be strong and safe. Plastics, metals, and semiconductors help the relay work in many places. No moving parts means it can handle bumps and shakes better than old relays.

Tip: Pick a solid-state relay if you want it to last a long time and work well.

Input Circuit

LEDs and Resistors

The input circuit in a solid-state relay uses LEDs and resistors. Engineers pick LEDs because they change electricity into light. This light starts the relay working. When the control voltage hits the LED, it lights up. The light then moves to the next part of the relay. Resistors work with LEDs to keep the current safe. Too much current can break the LED. The resistor stops this from happening. This helps the relay last longer and stay safe.

- LEDs: Make light when a control signal powers them.

- Resistors: Keep the current low to protect the LED.

Tip: Using the right LED and resistor helps the relay work fast and safe.

The input circuit often has more than one resistor. Some resistors make the relay more sensitive. Others block signals that are not needed. This helps the relay ignore noise and only react to real signals.

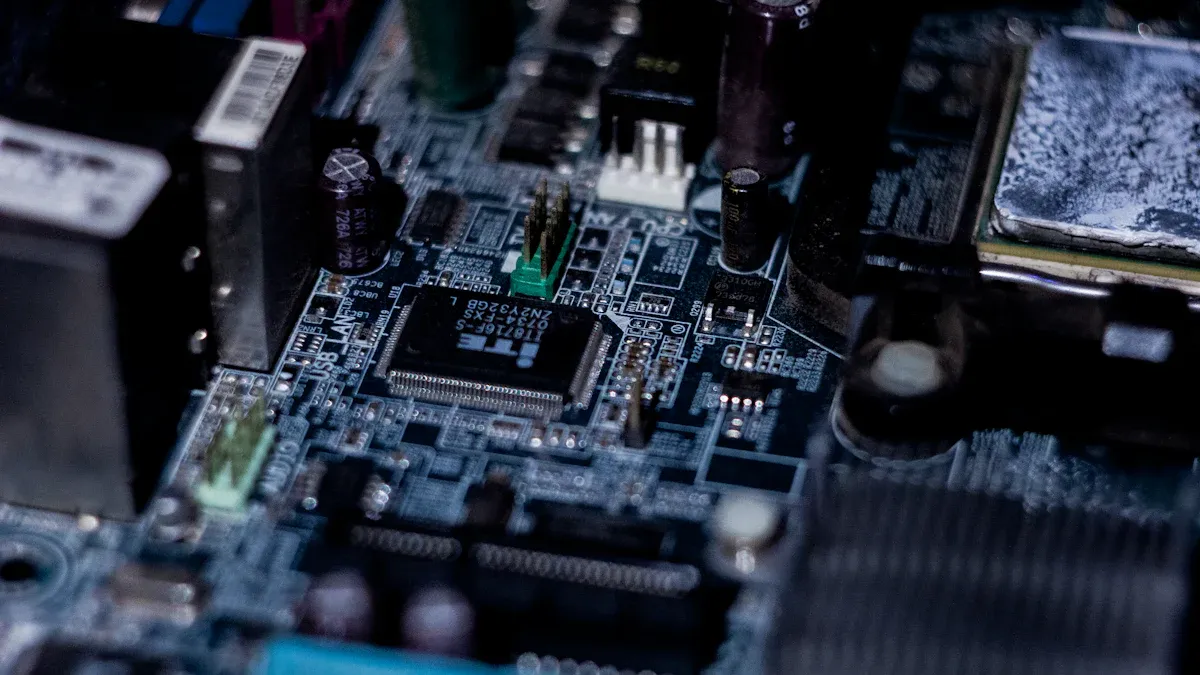

Circuit Board Materials

The input circuit sits on a printed circuit board, or PCB. Most PCBs are made from fiberglass-reinforced epoxy. This material makes the board strong and stable in heat or cold. Copper lines run across the board to connect the LEDs, resistors, and other parts. Solid-state relays use these boards because they can handle shock and vibration. No moving parts means the relay works well in tough places.

The PCB material keeps the relay safe from heat and stress. Manufacturers pick PCB materials that can take high heat. Some relays work where it gets up to 125°C or more. The board must not crack or melt. This keeps the relay working for a long time.

Note: A strong circuit board helps the relay work well in hard places. Good PCB material keeps the input circuit safe and working right.

Isolation and Control

Opto-Coupler

An opto-coupler is an important part of a solid-state relay. It uses light to keep the input and output apart. Inside, a near-infrared LED shines on a photo sensor. This makes an optical isolation channel. The relay sends signals through this channel without touching wires.

Opto-couplers come in different shapes. Some are flat. Others have a silicone dome that makes the LED and sensor farther apart. This helps the relay handle more voltage. Thicker channels or domes can let the relay work with up to 10 kV. These features help the relay stay safe in high-voltage places.

How well an opto-coupler works depends on many things. The current transfer ratio (CTR) changes with input current, temperature, and age. Engineers must think about these changes when they design circuits. Opto-couplers also block electromagnetic interference (EMI). They can handle voltage spikes and fast changes. This makes them good for tough jobs.

| Performance Characteristic | Explanation |

|---|---|

| Isolation Voltage | Up to 10 kV for high-voltage safety |

| EMI Resistance | Strong protection against interference |

| Power Consumption | Much lower than mechanical relays |

| Switching Speed | Fast, supports high-speed signals |

Note: Opto-couplers help solid-state relays last longer because there are no moving parts to wear out.

Controller Components

Controller components help turn the solid-state relay on and off. These parts include logic circuits, protection circuits, and sometimes microcontrollers. They help the relay answer control signals and keep it safe from harm. Solid-state relays use controller parts to keep input and output apart. This is called galvanic isolation.

It keeps sensitive electronics safe from high-voltage spikes and shocks. Controller circuits also add safety. For example, they can turn off the relay if the current is too high or if it gets too hot. Technical reports show controller parts make solid-state relays more reliable. They stop damage from short circuits and high startup currents. Some designs use special circuits to block voltage spikes and limit current. These features help the relay work safely in hard jobs like electric cars and factories.

Tip: Controller components make solid-state relays safer and more reliable, especially in high-power or high-voltage systems.

Solid-state relays use these smart controller parts for tough jobs. They keep the relay working even when things get rough. This makes them a good choice for many modern electrical systems.

Switching Components

FETs and Thyristors

Solid-state relays use FETs and thyristors as switches. These switches control how electricity moves inside the relay. FET means Field-Effect Transistor. Thyristors include Triacs and SCRs. Each one helps with switching in different ways. FETs work best in DC and low-voltage AC circuits. They can turn on and off very fast. MOSFETs are a kind of FET that switch in nanoseconds. This speed helps with fast data and automation. Thyristors like Triacs and SCRs work with AC loads. They control big amounts of power using small signals. Solid-state relays with FETs and thyristors have many good points:

- They have no moving parts, so they last longer than mechanical relays.

- They switch much faster, about 100 times quicker than electromechanical relays.

- There is no arcing or contact wear, so they are safer and last longer.

- They are very sensitive and work with low signals from logic circuits.

- They keep control and power sides separate for safety.

- They can work for hundreds of millions of hours without stopping.

- They are small and use power well, especially with MOSFETs.

Note: FETs and thyristors help solid-state relays do hard jobs where speed and reliability are important.

Thermal Interface Materials

FETs and thyristors can get hot when they work. Solid-state relays use thermal interface materials to handle this heat. These materials fill tiny spaces between hot parts and the heat sink. They help move heat away from important parts. Some common thermal interface materials are silicone pads, thermal grease, and special tapes. These materials keep the relay cool and safe.

Good heat control lets the relay handle high currents without breaking. Manufacturers pick thermal materials that fit the relay's power needs. Good cooling helps the relay last longer and work better. In high-power jobs, MOSFETs need extra cooling, so the right thermal material is very important.

Tip: Thermal interface materials stop the relay from getting too hot and help it last longer.

Protection and Housing

Snubber Circuits

Snubber circuits keep solid-state relays safe from voltage spikes. They also help with sudden changes in current. These circuits have a resistor and a capacitor. The resistor slows down electricity. The capacitor stores energy and lets it out when needed.

Together, they take in extra energy that could hurt the relay's switching parts. Engineers put snubber circuits on the relay's output. This stops high-voltage surges when the relay turns on or off. Without a snubber, voltage spikes can break the FETs or thyristors inside. Snubber circuits also cut down on electrical noise.

This helps the relay work better in loud places. Some solid-state relays use special snubber designs. These can handle higher voltages and faster switching. The parts in snubber circuits must take heat and stress. Good resistors and capacitors help the relay stay safe and last longer.

Tip: Snubber circuits protect solid-state relays in tough places by keeping important parts safe from harm.

Enclosure Materials

The outside of a solid-state relay uses strong plastics and metals. These materials keep dust, water, and bumps away from the inside. Makers pick plastics that do not melt or burn easily. They also use metals like aluminum or steel for strength and to help with heat.

Relay housings must pass strict safety tests. For example, they must not catch fire in glow wire tests. Many housings also follow rules to block water and other liquids. Some have tight seals and special coatings. These keep the relay safe during soldering and in wet or dirty spots. Solid-state relay enclosures are very tough:

- They resist moisture

- They resist mildew

- They resist corrosion

- They resist vibration

- They resist shock

- They can even stop explosions

These features make solid-state relays work well in factories, cars, and outside. The right enclosure keeps the relay working for many years, even in hard places.

Note: Strong housing materials keep the relay's electronics safe and help it pass safety rules for use in industry.

Comparison to Mechanical Relays

Material Differences

Solid-state relays and mechanical relays are made from different things. Solid-state relays use semiconductors like silicon and gallium arsenide. These materials help the relay switch quickly and have no moving parts. Mechanical relays use metal contacts, springs, and coils.

These parts move to open or close the circuit. The table below shows how these materials change how the relays work:

| Parameter | Solid-State Relay (SSR) | Mechanical Relay |

|---|---|---|

| Leakage Current (Off-State) | Up to 10 mA at 20°C | Approx. 277 nA (about 36,000 times less) |

| Voltage Rating Interpretation | Absolute maximum beyond which device destruction occurs | Service life limit; dielectric strength 10 to 100 times rated voltage |

| Thermal Management | Requires heat sinks to achieve rated current | Ratings apply directly to device as-is |

| Sensitivity to dv/dt & di/dt | Sensitive; requires snubber circuits to mitigate switching stresses | Not sensitive; no snubber needed |

Solid-state relays need heat sinks and snubber circuits. This is because semiconductors can get hot and are sensitive to fast voltage changes. Mechanical relays do not need these extra parts. Their metal contacts can handle heat and voltage spikes better. But, the metal parts wear out after a while.

Note: Solid-state relays use special materials for speed and safety. Mechanical relays use strong metals to last longer.

Lifespan and Performance

Solid-state relays last much longer than mechanical relays. They have no moving parts, so nothing wears out inside. This means they can switch on and off millions of times. Mechanical relays have contacts that touch and pull apart. Every time they switch, the contacts wear down a bit. After many uses, this makes the relay stop working. Solid-state relays also switch much faster. They can turn on and off in microseconds. Mechanical relays are slower because their parts must move. Solid-state relays are quiet when they work. Mechanical relays make a clicking sound each time they switch.

- Solid-state relays work well with vibration, dust, and moisture.

- They do not spark or arc, so there is less fire risk.

- They use less power when switching.

- Mechanical relays need good contact materials, like silver, to last longer.

- Solid-state relays need good cooling to stop them from getting too hot.

Mechanical relays may last for thousands of cycles. Solid-state relays can last for millions of cycles. This makes solid-state relays better for jobs that need to be fast, last a long time, and stay quiet.

Solid-state relays have special materials and clever parts for good performance. They use silicon, gallium arsenide, copper, and aluminum inside. These materials help the relay stay cool and last longer than mechanical relays. Good heat sinks and thermal interface materials help control the temperature. This makes the relay more reliable and helps it last longer. Since there are no moving parts, the relay does not wear out fast and works quietly. When picking a relay, people should check the materials and design to make sure it fits their needs.

FAQ

What materials help solid-state relays handle high temperatures?

Manufacturers use thermal interface materials like silicone pads and thermal grease. These materials pull heat away from important parts. Good heat control helps the relay last longer. It also keeps the relay safe in hot places.

What makes solid-state relays different from mechanical relays?

Solid-state relays use semiconductors, plastics, and metals. They do not have any moving parts inside. Mechanical relays use metal contacts and springs that move. Solid-state relays last longer and switch faster because of their special materials.

What protects the inside of a solid-state relay from dust and water?

Strong plastic and metal enclosures keep the relay safe. These housings block dust, water, and bumps from getting inside. Some enclosures have seals or coatings for extra safety in tough places.

What role do opto-couplers play in a solid-state relay?

Opto-couplers use light to keep input and output circuits apart. This separation keeps sensitive electronics safe from high voltage and noise. Opto-couplers help the relay work safely.

What components prevent voltage spikes in solid-state relays?

Snubber circuits use resistors and capacitors together. These parts take in extra energy from voltage spikes. Snubber circuits protect the relay's switching parts and help it last longer.