Calculating the size of the relay is very important. It keeps your electrical system safe and working well. A relay that's too small can get too hot or break. A relay that's too big can cost more money than needed. To calculate the size of the relay, think about voltage, current, and the type of load. Doing this helps stop problems and makes your equipment last longer. It also saves you time and money.

Key Takeaways

Pick a relay with a voltage rating a bit higher than your system's voltage to avoid overheating or damage.

Choose a relay with a current rating 20-30% higher than your system's highest current for extra safety.

Know if your load is AC or DC and whether it is inductive or resistive to match it with the right relay.

Think about things like temperature and humidity when picking a relay to make it last longer.

Add safety margins and follow rules to keep your system safe and working well.

Understanding the Basics of Relays

What is a relay and why is it important?

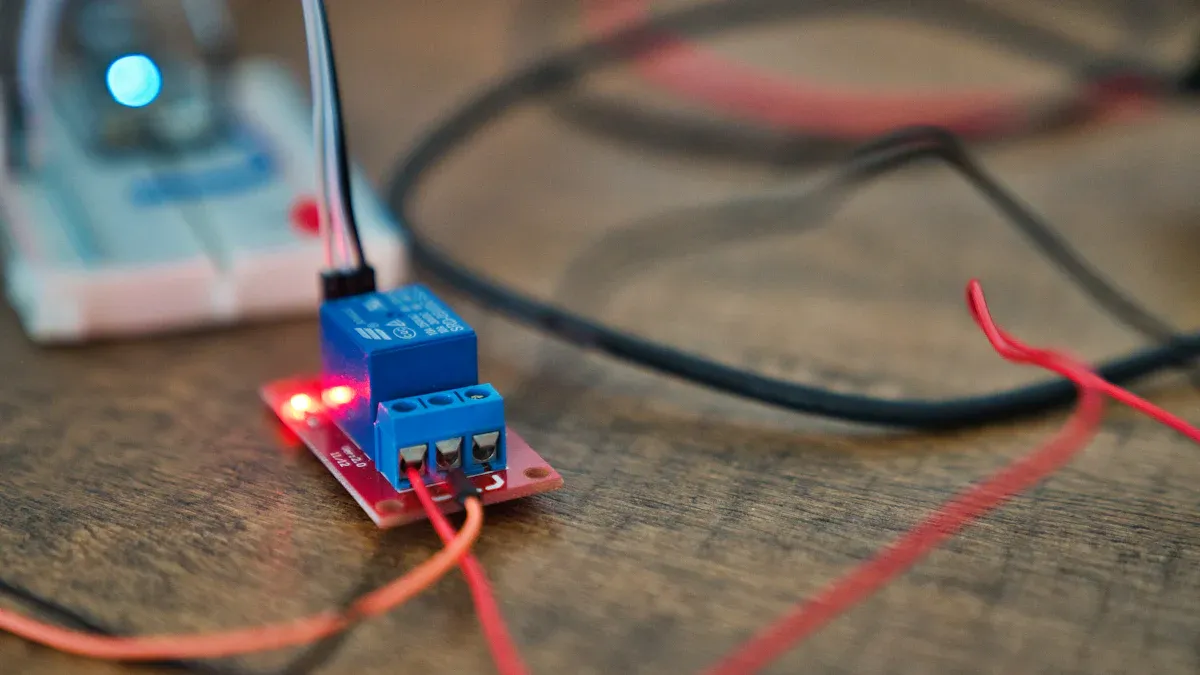

A relay is a switch for electricity. It uses a small signal to control a bigger electrical load. Think of it as a helper that keeps your devices safe. Relays protect systems from damage caused by too much voltage or current. They also help automate systems, making them work better and more reliably.

Relays are very important in today's electrical systems. For example, electromechanical relays (EMRs) find problems like overloads in electrical lines. Solid-state relays (SSRs) switch faster and last longer. They are great for delicate systems like phones. Without relays, many machines would not work properly.

Types of relays and their common applications

Relays come in different types for different jobs. Here's a simple guide:

|

Type of Relay |

What It Does |

Where It's Used |

|---|---|---|

|

Electromechanical Relays (EMR) |

Keeps systems safe from high voltage or current. |

Lights, electronics protection, motor controls. |

|

Solid-State Relays (SSR) |

Switches faster and lasts longer than EMRs. |

Phones, sensitive devices, automated machines. |

|

Reed Relays |

Small and good for low-power tasks. |

Computers, everyday gadgets. |

Relays are also used in smart systems to do logic tasks. Power relays are key in home appliances like washing machines. They are also used in solar panels. Time relays help by controlling when things turn on or off. These examples show how relays make systems work better and last longer.

By learning about relay types and uses, you can pick the right one. This keeps your system safe and working well.

Key Factors to Calculate the Size of the Relay

When picking a relay, think about key factors. These factors help the relay work safely and properly. Let's look at them step by step.

Voltage rating: Match the relay to your system's voltage

The voltage rating shows the highest voltage the relay can handle. It must match your system's voltage. If the rating is too low, the relay might fail or overheat. A relay with a much higher rating may not work well.

For example, if your system uses 120 volts, pick a relay rated slightly above 120 volts. This protects it from small voltage spikes. Always check the relay's datasheet for its voltage details. This step is very important when choosing a relay.

Tip: Never use a relay with a lower voltage rating than your system. It can cause dangerous problems.

Current rating: Find the right current capacity

The current rating shows how much current the relay can handle. To choose the right one, know the maximum current your system uses. A relay with a lower rating can overheat and break.

For instance, if your system uses 10 amps, pick a relay rated for at least 10 amps. Adding a safety margin, like choosing 12 or 15 amps, is smart. This helps the relay last longer and handle extra current safely.

Note: Relays with higher current ratings cost more and are bigger. Pick one that balances cost and performance.

Load type: AC vs. DC loads and inductive vs. resistive loads

The type of load also matters when choosing a relay. Loads can be AC (alternating current) or DC (direct current). AC loads are common in homes, while DC loads are used in battery devices. Relays for AC loads may not work well with DC loads.

You also need to know if the load is inductive or resistive. Inductive loads, like motors, create magnetic fields and voltage spikes. Resistive loads, like heaters, don't have this problem. Relays for inductive loads are made to handle these spikes.

Example: If you're using a motor (an inductive load) with DC power, pick a relay made for DC inductive loads. This keeps it working well and prevents damage.

By knowing these factors-voltage, current, and load type-you can pick the right relay. This helps your system stay safe and work well.

Safety Margins: Keeping Your System Safe and Durable

When picking a relay, always add a safety margin. This helps the relay work well in normal and tough conditions. A safety margin protects the relay from sudden voltage or current spikes.

Why Safety Margins Are Important

Electrical systems don't always stay steady. For example, motors use more current when starting. Power surges can also happen anytime.

Without a safety margin, these changes can harm the relay. It might overheat or stop working. Adding a safety margin lets the relay handle these changes safely.

Tip: Choose a relay with voltage and current ratings 20-30% higher than your system's needs. This extra room helps the relay handle surprises.

How to Use Safety Margins

To find the right relay size with a safety margin, first check your system's highest voltage and current. Multiply these numbers by 1.2 or 1.3 to get the minimum ratings. For example:

If your system uses 10 amps, pick a relay rated for 12 or 13 amps.

If your system runs on 120 volts, choose a relay rated for 144 to 156 volts.

This way, the relay can handle sudden surges without breaking.

Balancing Safety and Cost

Safety margins are important, but don't overdo it. Relays with very high ratings can be too big and costly. Find a relay that fits your system and has enough extra capacity for surprises.

By using safety margins, you protect your system and make your relay last longer. This simple step saves time and money over time.

Step-by-Step Guide to Calculate the Size of the Relay

Step 1: Collect system details (voltage, current, load type)

Start by gathering important information about your electrical system. These details help you pick a relay that fits your needs. Focus on three main things: voltage, current, and load type.

Voltage Rating

The relay's voltage rating must be equal to or higher than your system's voltage. This keeps the relay safe from overheating or breaking.

Current Rating

Find out the highest current your system uses. The relay should handle this current, including sudden surges from devices like motors.

Load Type

Check if your load uses AC or DC power. Also, see if it's inductive or resistive. Inductive loads need relays that can handle voltage spikes caused by magnetic fields.

Here's a simple table to help:

|

Specification Type |

What It Means |

|---|---|

|

Voltage Rating |

Must be equal to or higher than the voltage powering your load. |

|

Surge Current Durability |

Relay must handle sudden high currents without damage. |

By collecting these details, you're ready to choose the right relay for your system.

Step 2: Check relay datasheets for matching specifications

After gathering system details, look at datasheets from relay makers. Datasheets show what the relay can do, like voltage and current limits, load types, and safety features.

How to Use Datasheets

Look for key details like:

Voltage and Current Ratings: Make sure they meet or exceed your system's needs.

Switching Capacity: Confirm the relay can handle your load size and type.

Environmental Limits: Check if the relay works well in your system's conditions.

Why Datasheets Are Important

Datasheets prevent mismatches between your system and the relay. For example, if your system uses a DC motor, the datasheet will show if the relay works with DC inductive loads. This step ensures the relay works properly.

Step 3: Check environmental conditions (temperature, humidity, etc.)

The environment affects how well a relay works. Temperature and humidity can change its durability and performance. Before choosing, check where your system will operate.

Important Environmental Factors

Relays are tested under normal conditions, like 15°C to 35°C and 25%-75% humidity. Outside these ranges, problems can happen, such as:

Contact Damage: High heat and humidity can harm relay contacts.

Condensation: Sudden temperature changes can cause water buildup inside the relay.

Here's a table showing environmental effects:

|

Condition Description |

Effect on Relay Performance |

|---|---|

|

Relays are tested in normal conditions (15°C-35°C, 25%-75% humidity). |

Ensures reliable operation within these limits. |

|

High heat and humidity can damage relay contacts. |

May cause contact failure and reduce relay performance. |

|

Sudden temperature changes can create condensation inside the relay. |

Can lead to insulation problems and make the relay less reliable. |

How to Check Environmental Conditions

Look at the datasheet for the relay's temperature and humidity limits. Compare these to your system's environment. If your system faces extreme conditions, pick a relay built for tough environments.

By checking environmental factors, you make sure the relay works well and lasts longer in your system.

Step 4: Add safety margins and follow industry rules

Adding safety margins and following rules are key steps. These steps keep your system safe and meet important regulations. Let's break it down into simple actions.

Why Safety Margins Are Needed

Safety margins give extra room for your relay to handle surprises. Electrical systems don't always work perfectly. For example, motors use more current when starting. Power surges can also happen suddenly. Without a safety margin, your relay might break early. This can lead to expensive fixes or delays.

Tip: Pick a relay with voltage and current ratings 20-30% higher than your system's needs. This helps the relay handle sudden changes safely.

How to Find Safety Margins

Follow these steps to add safety margins:

Find your system's highest voltage and current.

For example, if your system runs at 120 volts and 10 amps, use these numbers.

Add extra room for safety.

Multiply your voltage and current by 1.2 or 1.3 to allow for surges.

Voltage: ( 120 \times 1.2 = 144 ) volts

Current: ( 10 \times 1.2 = 12 ) amps

Choose a relay that matches or beats these numbers.

In this case, pick a relay rated for at least 144 volts and 12 amps.

This extra room helps your relay work well in tough situations.

Following Industry Rules

Industry rules make sure your relay is safe and works well. Rules differ by location and use, but they protect people and equipment.

Here are some common rules to know:

|

Rule |

What It Does |

|---|---|

|

UL (Underwriters Laboratories) |

Checks if the relay is safe for electrical systems. |

|

IEC (International Electrotechnical Commission) |

Sets worldwide rules for performance and reliability. |

|

RoHS (Restriction of Hazardous Substances) |

Makes sure the relay doesn't have harmful materials like lead. |

How to Check for Rule Compliance

Look for certifications on the relay.

Labels like "UL Listed" or "IEC Certified" show the relay passed safety tests.

Make sure it fits your region's rules.

For example, in the U.S., check for UL compliance. In Europe, look for CE marking.

Ask the maker if you're unsure.

Contact the company for details about the relay's certifications.

Note: Using relays that don't follow rules can be unsafe and cause legal trouble. Always pick certified parts for your system.

Balancing Safety Margins and Rules

Safety margins and rules are both important. They need to work together. A relay with a big safety margin but no certifications might not be safe. A certified relay without enough safety margin might fail under stress. Choose a relay that balances both for the best results.

By adding safety margins and checking rules, you make your system strong and reliable. These steps protect your equipment and ensure everything meets the right standards.

Common Mistakes When Sizing a Relay

Picking a relay that's too small

Using a relay that's too small can cause big problems. It won't handle your system's voltage or current needs. This can make it overheat, break, or stop working. For example, if your system needs 15 amps but you use a 10-amp relay, it will likely fail.

A small relay also wears out faster. The extra strain damages its parts quickly. This means you'll need to replace it more often, costing time and money. To avoid this, pick a relay with ratings higher than your system's needs.

Tip: Find your system's highest voltage and current. Then, choose a relay rated 20-30% higher.

Forgetting load type differences

Different loads need different relays. Ignoring this can make your relay fail early. Inductive loads, like motors, create voltage spikes when turned on or off. These spikes can harm relays not built for them. Resistive loads, like heaters, don't have spikes and are easier on relays.

Relays for AC loads may not work well with DC loads. DC loads need relays with stronger contacts because DC arcs are harder to stop. Using the wrong relay can cause poor performance or system failure.

Example: If you're using a motor (an inductive load), pick a relay made for inductive loads. It will handle the spikes safely.

Ignoring the environment

Where the relay works affects how long it lasts. High heat can overheat coils, and humidity can cause rust. Shocks and vibrations can damage the relay's parts, making it less reliable.

Relays are tested in normal conditions, like 15°C to 35°C and 25%-75% humidity. Outside these ranges, they wear out faster. For example, under normal conditions, relays last about 1200 hours without failing. Extreme conditions can shorten this time.

|

Environmental Factor |

Effect on Relay Performance |

|---|---|

|

Shocks and Vibrations |

Can damage internal parts, reducing reliability. |

|

Temperature Changes |

High heat can overheat coils, shortening lifespan. |

|

Humidity |

Causes rust and water buildup, harming performance. |

|

Time-to-Failure (TTF) |

Relays last about 1200 hours under normal conditions but less in extreme environments. |

Always check the relay's datasheet for its environmental limits. If your system faces tough conditions, choose a relay made for those situations.

Note: Ignoring the environment can lead to failures and expensive repairs. Match the relay to where it will be used.

Choosing the right relay size keeps your system safe and working well. Think about voltage, current, load type, and safety margins. This lowers the chance of problems and helps your equipment last longer.

Relays in important systems, like airplanes, need careful checks. Aging and weather can cause hidden issues that are hard to spot. Good tools find these problems early, keeping devices and people safe.

Don't make mistakes like picking a relay that's too small or ignoring the environment. By following these tips, your system will be strong and last a long time.

FAQ

What happens if I pick a relay with a higher rating?

Choosing a relay with a much higher rating costs more money. It might also work less efficiently. It won't damage your system, but it's smarter to pick a relay that fits your system's needs. Add a safety margin for extra protection.

Can one relay work for both AC and DC loads?

No, it can't. AC and DC loads act differently. DC loads need relays with stronger parts to handle arcs. Always check the relay's datasheet to make sure it works with your load type.

How can I tell if my load is inductive or resistive?

Inductive loads, like motors, create magnetic fields and voltage spikes. Resistive loads, like heaters, use power without spikes. Look at your device's details or ask the maker to find out the load type.

Why do relays break in tough environments?

Hot temperatures can overheat the relay's coil. Humidity can cause rust or water buildup. These problems harm the relay's parts and shorten its life. Pick a relay made for your system's conditions to avoid these issues.

Should I replace relays often?

Relays don't need replacing often if they're sized right and used properly. Check them regularly for damage, especially in hard-working systems. Replace them if you see overheating, rust, or bad performance.