Solid state relays and contactors work in different ways. They also last for different amounts of time. Solid state relays switch on and off in about 1 millisecond. They can last up to 100,000 cycles. Contactors take 5 to 15 milliseconds to switch. They wear out faster than solid state relays. The table below shows these differences:

| Performance Metric | Solid State Relays | Contactors |

|---|---|---|

| On/Off Cycle Lifetime | Up to 100,000 | Wears out faster |

| Switching Speed | ~1 ms | 5–15 ms |

| Contact Resistance | ~100 ohms | Tens of milliohms |

These differences change how each device works with lots of use. They also affect how reliable each one is. Energy loss is different for each device too. Knowing these facts helps people pick the right device.

Key Takeaways

- Solid state relays turn on and off very fast. They last a long time. They are quiet because they do not have moving parts.

- Contactors can control bigger machines and heavy loads. But they wear out faster because they have moving metal parts.

- Solid state relays are good for quick and often switching. They are also good in places where noise is a problem. Contactors are better for big jobs and when you do not switch often.

- Taking care of both devices helps them last longer. Keep contactors clean. Check solid state relays to make sure they do not get too hot.

- You should pick the right device for your needs. Think about how big the load is, how fast you need to switch, and safety. This helps everything work well and safely.

Operation

Mechanism

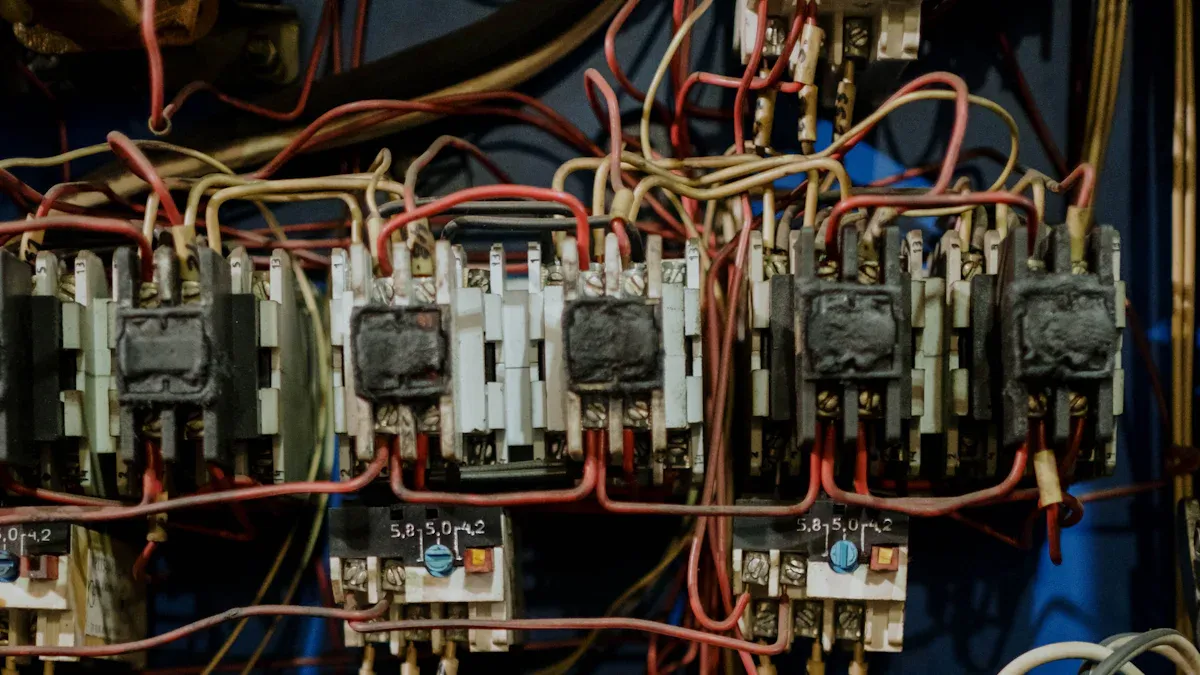

Solid state relays and contactors control electricity in different ways. A contactor is a switch that uses magnets to work. It has a coil that makes a magnetic field. This field pulls a part called an armature.

The armature moves metal pieces to open or close the circuit. Springs hold the contacts in place when the coil is off. This setup lets contactors handle big amounts of power. But the moving parts can break down after a while. Solid state relays use electronics instead of moving parts. They have three main parts: input, drive, and output circuits.

The input gets a signal and turns on a light inside an optocoupler. The drive part keeps the control side and load side apart. The output uses special parts like MOSFETs or thyristors to turn the load on or off. This switching is much faster than moving parts. The table below compares the two types:

| Parameter | Electromechanical Relay (EMR) | Solid State Relay (SSR) |

|---|---|---|

| Switching Mechanism | Uses physically moving contacts actuated by electromagnetic forces. | Uses semiconductor and optocoupler-based electronic switching without moving parts. |

| Power Consumption | Requires higher input power depending on switching voltage and contact resistance. | Requires less input power with low internal circuit consumption. |

| Shock & Vibration | Sensitive to shock and vibrations due to mechanical parts. | Highly resistant to shock and vibrations. |

| Electrical Noise | Generates signal noise due to electromagnetic operation. | Generates less electrical disturbance; zero voltage turn-on/off. |

| Compatibility | Cannot operate well in high electromagnetic interference areas; generates arcs when interrupting current. | Not affected by electromagnetic forces; no arc generation or contact bounce. |

| Switching Speed | Responds in approximately 5 to 15 milliseconds. | Responds within about 100 microseconds. |

| Positional Sensitivity | Sensitive to orientation due to mechanical system. | Insensitive to mounting position; can be mounted vertically or horizontally. |

Tip: Both solid state relays and contactors control power. Their designs make them better for different jobs. Solid state relays switch faster and do not make much noise.

No Moving Parts

Solid state relays have no moving parts at all. This gives them some big benefits. First, no moving contacts means nothing wears out from rubbing. The device does not get damaged by friction or metal getting tired. This helps it last longer and need less fixing. Second, solid state relays are quiet when they work. Contactors make a click when they switch.

Solid state relays do not make this sound. This makes them good for places where you need quiet. Any noise from solid state relays comes from electronics, not from moving parts. This noise is much softer than the sound from moving parts. Third, solid state relays can handle shaking and bumps. Machines that move can cause trouble for contactors because their parts can shift or break. Solid state relays keep working even if things shake. They also do not have problems like arcing, which happens when metal contacts open or close with power on. This makes them safer in places where sparks could start fires or explosions.

- Solid state relays switch faster than contactors.

- They do not make sparks or loud sounds.

- They last longer because there are no parts to wear out.

- They work well where there is shaking or lots of electrical noise.

These good points make solid state relays useful for many new uses. But contactors are still needed for big power jobs where you need mechanical switching.

Switching Speed

Response Time

Switching speed measures how fast a device can turn on or off. This speed matters in many electrical systems. Solid state relays respond almost instantly. Most models switch in less than one millisecond. This quick action comes from their electronic design. No moving parts slow them down. Contactors work slower.

They use magnets and moving metal parts. These parts need time to move and settle. Most contactors take between five and fifteen milliseconds to switch. This delay can affect machines that need fast changes. For example, in some control systems, a slow response can cause errors or missed signals. A fast response time helps protect equipment. If a problem happens, a solid state relay can shut off power quickly. This quick action can stop damage or overheating. In contrast, a contactor may not react fast enough in some cases.

Note: Fast switching also means less wear and tear for solid state relays. Their parts do not rub or spark, so they last longer.

High-Frequency Use

Some machines need to switch on and off many times each second. This is called high-frequency use. Solid state relays handle this job well. They can switch thousands of times per second without problems.

Their electronic parts do not get tired or worn out from fast switching. Contactors cannot keep up with high-frequency tasks. Their moving parts heat up and wear out quickly. If used too often, they may fail or need repairs. This makes them less useful for jobs that need rapid or repeated switching.

- Solid state relays work best in high-speed and high-frequency systems.

- Contactors suit jobs where switching happens less often.

A table can help compare their performance:

| Feature | Solid State Relay | Contactor |

|---|---|---|

| Typical Response Time | < 1 ms | 5–15 ms |

| Max Switching Rate | Very high | Low |

| Wear from Fast Use | Minimal | High |

Durability & Lifespan

Wear Factors

How long a device lasts depends on what wears it out. Contactors have metal parts that move. When they turn on or off, the metal touches and pulls apart. This makes heat and sometimes sparks. Over time, the metal can get burned or have holes. Dirt and dust can get inside and make the parts stick. Shaking or bumps can move the parts out of place.

These things make contactors wear out faster. Solid state relays do not have any moving parts. They use electronics to switch power. This means they do not have problems from rubbing or worn contacts. But solid state relays have other things that can wear them out. Even when off, a little bit of current leaks through.

This is about 10mA when it is not hot. If it gets hotter, more current leaks. Contactors leak much less current, almost 36,000 times less. Too much leakage can make heat and stress the relay. Fast changes in power can also hurt the electronic parts. If there is no protection, these things can make the relay wear out sooner.

Note: Good design helps both devices last longer. Using snubbers and cooling for solid state relays, and keeping contactors clean, can help stop wear.

| Wear Factor | Contactor (Mechanical) | Solid State Relay (Electronic) |

|---|---|---|

| Moving Parts | Yes | No |

| Contact Erosion | High | None |

| Leakage Current | Very Low | Moderate, increases with heat |

| Vibration Sensitivity | High | Low |

| Thermal Stress | Moderate | High without cooling |

Maintenance

Each device needs different care. Contactors need to be checked often. Workers look for worn metal, loose wires, and dirt. Sometimes they must change the metal parts or clean inside. If a contactor is loud or does not work, it may need fixing or replacing. Solid state relays do not need as much care. They do not have metal contacts to clean or change. But they need to stay cool.

If they get too hot, the electronics can break. Workers should look for heat damage or too much leakage current. Adding fans or heat sinks can help keep them cool. Special circuits, like snubbers, can stop power spikes from hurting them. A simple checklist helps both devices work well:

- Look for signs of heat or damage.

- Keep the area clean and free of dust.

- Check the wires.

- For solid state relays, watch for more leakage current.

Taking care of both types helps them last longer. Good care means fewer problems and safer use.

Size & Efficiency

Compact Design

Solid state relays are built with semiconductor parts. This makes them much smaller than contactors. They can fit into small spaces on control panels or inside machines. Their small size helps engineers save space. It also lets them build smaller devices. Contactors have big coils and metal contacts. These parts take up more space. Factories need bigger boxes to fit contactors, especially for high currents. A table shows how their size and design are different:

| Parameter | Solid State Relay (SSR) | AC Contactor |

|---|---|---|

| Size | More compact, semiconductor-based | Larger, mechanical with coil/contacts |

| Maintenance | Low, no moving parts | More, due to mechanical wear |

Tip: Smaller devices are easier to install. They can also lower the cost of cabinets and wiring.

Power Loss

Saving energy is important in all electrical systems. Solid state relays use less coil power than contactors. Their electronic circuits need less energy to turn on and off. This helps save electricity over time.

But solid state relays can get hot when working. They often need heat sinks to stay cool. If they get too hot, the relay can break. Contactors use more coil power. Their coils and moving parts waste more energy as heat. They make less heat at the contacts, but use more energy overall. This means higher costs, especially if they switch a lot. A table helps show these differences:

| Parameter | Solid State Relay (SSR) | AC Contactor |

|---|---|---|

| Coil Power Consumption | Lower | Higher |

| Heat Generation | More, needs heat sinks | Less, but more coil power used |

| Energy Efficiency | High, but needs thermal management | Lower, more energy lost in coil |

- Solid state relays save space and use less energy to switch.

- Contactors need more space and use more power, but can handle bigger currents.

Safety & Applications

Protections

Solid state relays and contactors keep electrical systems safe in different ways. Solid state relays use optical isolation. This keeps control signals away from dangerous voltages. Many solid state relays have built-in protection for too much current or voltage. These features stop damage from power surges or short circuits. Solid state relays do not make sparks or arcs.

This lowers the chance of fire or electric shock. Contactors do not have as many safety features inside. They mostly rely on their design and outside fuses or circuit breakers. When a contactor opens or closes, it can make an arc. This arc can wear out the contacts and cause safety problems. Contactors also make a loud click when they work. If the sound changes, it might mean something is wrong. The table below shows how their safety features compare:

| Safety Feature | Solid State Relays (SSRs) | Mechanical Contactors |

|---|---|---|

| Optical Isolation | Yes | No |

| Overcurrent Protection | Built-in (many models) | External only |

| Overvoltage Protection | Built-in (many models) | External only |

| Arc Generation | None | Yes, during switching |

| Operation Noise | Silent | Audible clicking |

Tip: Solid state relays have more built-in protections. They help keep people and equipment safer, especially where safety matters most.

Typical Uses

Solid state relays and contactors are used for different jobs. Solid state relays are best for places that need fast and quiet switching. They often control lights, heaters, and small motors. Factories use them in machines that need quick and reliable power. Solid state relays are also good for medical devices and computers. They do not make noise or sparks.

Contactors are used for bigger jobs. They control large motors, pumps, and heavy machines. Many buildings use contactors for lights, heating, and air conditioning. Contactors work well where switching does not happen a lot. Their strong contacts can handle starting and stopping big equipment. Here are some common uses:

- Solid state relays: factory automation, temperature control, lighting, medical devices, computer servers.

- Contactors: motor control, HVAC, big pumps, heavy machines, building lighting panels.

Note: Pick the right device based on the size of the load, how often you switch, and if you need quiet or spark-free work

Choosing Solid State Relays and Contactors

Choosing the right device keeps people and equipment safe. Solid state relays and contactors each have their own strengths. Solid state relays switch fast, work quietly, and have built-in safety features.

They last longer because they do not have moving parts. Picking the right solid state relay helps things run smoothly and cuts down on repairs. It also saves money and time. Contactors are better for big loads and tough places. They can handle high currents and are easy to replace if they break. But using the wrong device can cause trouble.

A solid state relay that is too small can get too hot or stop working. A contactor used for fast switching can wear out quickly and cause mistakes. Experts say to check the type of load before picking a device. Loads can be resistive, like heaters, inductive, like motors, or capacitive, like some lights. Each type needs a different relay or contactor. Knowing what you need helps stop short circuits, overheating, and fire risks. The table below sums up the main points for choosing:

| Selection Factor | Solid State Relays (SSRs) | Mechanical Contactors |

|---|---|---|

| Best for | Fast, frequent, silent switching | High current, heavy-duty loads |

| Built-in Protections | Yes | No (external needed) |

| Maintenance Needs | Low | Higher |

| Application Examples | Automation, electronics, lighting | Motors, HVAC, industrial loads |

⚠️ Always match the device to the type of load and how often you switch. The right choice makes things safer, more reliable, and more efficient.

Solid state relays and contactors do not work the same way. Each one is good for different jobs. Solid state relays turn on and off very fast. They last a long time and are quiet. Contactors can control bigger machines and heavy equipment. Before picking one, people should look at how much power is needed. They should also think about how fast it must switch and if safety is important. Both solid state relays and contactors help electrical systems in their own ways.

FAQ

What is the main difference between a solid state relay and a contactor?

A solid state relay switches power with electronic parts. A contactor uses metal parts that move. Solid state relays work faster and last longer. Contactors can handle bigger jobs and heavy machines.

Can solid state relays replace contactors in all applications?

Solid state relays cannot be used everywhere. They are best for quick, frequent switching and smaller loads. Contactors are better for big motors and heavy equipment. Always check what you need before picking one.

Why do solid state relays not make noise?

Solid state relays do not have moving parts. They use electronics to switch on and off. This makes them quiet when working. Contactors make a click because their metal parts move.

Do solid state relays need maintenance?

Solid state relays need very little care. There are no contacts to clean or change. People should check for heat damage and keep them cool. Good airflow helps stop them from getting too hot.

Are solid state relays safer than contactors?

Solid state relays have more built-in safety features. They do not make sparks or arcs. This lowers the chance of fire or shock. Many have optical isolation and surge protection. Contactors need extra safety parts to be as safe.