Electromechanical relays, commonly known as EMR, function like switches by using an electromagnetic coil to open or close circuits. The full electrical name of EMR is Electromechanical Relay. In electrical engineering, an Electromechanical Relay is a device that controls high power circuits with low power signals. While EMR can also refer to medical records or electromagnetic radiation, in this context, EMR specifically means Electromechanical Relay. Many industries rely on the Electromechanical Relay for its reliable switching capabilities.

The table below highlights why the Electromechanical Relay remains important in industry:

|

Aspect |

Details |

|---|---|

|

Market Size (2023) |

USD 6592.01 million |

|

Largest Market Segment (2023) |

Industrial automation |

|

Unique Strengths |

High switching capacity, strong build, dependable |

Key Takeaways

Electromechanical relays, or EMRs, use a coil with magnetism to open or close circuits. This lets small signals control big amounts of power in a safe way.

In electrical engineering, EMR stands for Electromechanical Relay. This is not the same as electronic medical records or electromagnetic radiation.

The main parts of an EMR are contacts, an armature, and a coil with magnetism. These parts work together to switch circuits in a reliable way.

Picking the right coil voltage, current, and contact materials helps the relay work well. It also helps the relay last longer.

EMRs are used a lot in industries to control motors, lights, and machines. They are popular because they switch power well and keep electricity separated.

EMR Meaning in Electrical Engineering

The Full Electrical Name of EMR

In electrical engineering, EMR stands for Electromechanical Relay. Engineers use this name for a device that switches circuits. It works by moving parts when an electromagnetic field is present. The full name shows that the device has both electrical and mechanical parts. The relay uses an electromagnetic field to move contacts. This lets it control how electricity flows. You can find the full name in textbooks and guides. When engineers say EMR, they mean a relay that uses an electromagnetic field. The full name makes it clear this device is not about patient records or health data.

EMR vs. Electronic Medical Records

Many people think EMR means electronic medical records. Hospitals and clinics use these records for patient information. They include history, test results, and treatments. Electronic health records are like electronic medical records but have more details. They can be shared with other healthcare providers. Electronic medical records focus on one patient and one doctor.

Electronic health records connect records from many places. Healthcare technology uses both types to help patients. Doctors and nurses use electronic medical records to keep track of patient data. Electronic health records help them share information with others. The full name of EMR in engineering does not mean medical records. In electrical engineering, EMR means Electromechanical Relay, not health data.

Tip: Always check what EMR means in your situation. In hospitals, EMR means electronic medical records or electronic health records. In engineering, EMR means Electromechanical Relay.

EMR vs. Electromagnetic Radiation

Some people think EMR means electromagnetic radiation. In science, electromagnetic radiation is waves that carry energy. These waves include radio, microwave, infrared, visible light, ultraviolet, X-rays, and gamma rays. Electromagnetic radiation moves as fast as light. It does not need anything to travel through. The electromagnetic field makes these waves.

An electromagnetic field helps move the waves. Books like Purcell and Morin's 'Electricity and Magnetism' say electromagnetic radiation has electric and magnetic fields at right angles. Browne's 'Physics for Engineering and Science' says electromagnetic radiation carries momentum and can push things when absorbed. Engineers use electromagnetic radiation to talk about energy and waves. The full name of EMR does not mean electromagnetic radiation. In electrical engineering, EMR means Electromechanical Relay, not radiation or waves.

|

Term |

What It Means in Context |

Used For |

|---|---|---|

|

EMR (Electromechanical Relay) |

Switches circuits with electromagnetic field |

Electrical engineering |

|

EMR (Electronic Medical Records) |

Stores patient records and health data |

Healthcare technology |

|

EMR (Electromagnetic Radiation) |

Waves of energy from electromagnetic field |

Physics and engineering |

How EMR Works

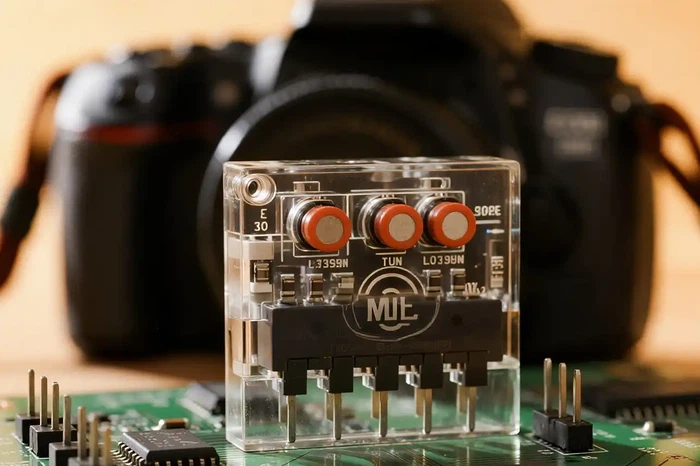

Components

An electromechanical relay has many important parts. Each part has a special job in the relay. The main parts are contacts, an armature, and an electromagnetic coil. The table below lists what each part is made of:

|

Component |

Material Description |

|---|---|

|

Contacts |

Made from highly conductive and arc-resistant materials such as silver, tungsten, palladium. |

|

Armature |

Made of metal attracted by the electromagnetic coil; acts as the movable conducting part. |

|

Electromagnetic Coil |

Wire wound around a ferromagnetic core to generate magnetic field when energized. |

Contacts let electricity pass through the relay. They must last a long time and handle strong currents. Silver, tungsten, and palladium help them work well and not break.

Armature is a moving part inside the relay. It moves when the electromagnetic field pulls it. The armature opens or closes the contacts.

Electromagnetic coil makes a magnetic field when power goes through it. The coil is wrapped around a core made of iron or another magnetic metal.

Note: The materials used can change how well the relay works and how long it lasts.

Operation

An electromechanical relay uses a magnetic field to move its parts. The steps happen in a certain order:

The relay coil gets a control voltage. This makes a magnetic field.

The magnetic field pulls the armature closer to the coil.

The armature moves the contacts. Normally open (NO) contacts close, and normally closed (NC) contacts open.

This lets current flow through the load circuit.

When the control voltage stops, the magnetic field goes away.

The armature moves back to where it started.

The contacts go back to normal, and the current stops.

This lets a small signal control a bigger load. The relay keeps the control side and power side apart. This helps protect sensitive parts from high voltage.

The table below shows the differences between electromechanical relays (EMR) and solid-state relays (SSR):

|

Feature |

Electromechanical Relay (EMR) |

Solid State Relay (SSR) |

|---|---|---|

|

Principle of Operation |

Uses electromagnetic force to physically open/close contacts |

Uses semiconductor devices to switch circuits electronically |

|

Moving Parts |

Yes, includes coil, spring, and contacts |

No moving parts |

|

Switching Speed |

Slower (5-15 milliseconds) |

Much faster (microseconds) |

|

Power Consumption |

Higher, due to electromagnetic components |

Lower, often milliwatts |

|

Noise Generation |

Generates mechanical and electrical noise |

Minimal noise |

|

Electrical Isolation |

Provides isolation but less effective due to physical contacts |

Superior isolation, no physical contact |

|

Shock & Vibration |

Sensitive, can be damaged by mechanical shock |

Highly resistant due to no moving parts |

|

Lifespan |

Limited, wears out after several hundred/thousand cycles |

Long, millions of cycles without degradation |

|

Size |

Larger, requires more space for mechanical parts |

Smaller and more compact |

|

Cost |

Lower initial cost, but higher maintenance/replacement costs |

Higher initial cost, but more durable and reliable |

|

Application Suitability |

Suitable for high-load, cost-sensitive applications |

Ideal for high-speed, long-life, and harsh environment uses |

Electromechanical relays use a magnetic field to move contacts. This makes a clicking sound and can wear out after a while. Solid-state relays use electronic parts and do not have moving pieces. They switch faster and last longer, but they cost more.

Tip: Always use the right coil voltage and contact rating for your needs. Good wiring and regular checks help stop relay problems.

Design Factors

Voltage and Current

Voltage and current ratings are very important when picking a relay. Every relay has a set coil voltage and coil current. These must match the control circuit. The contact ratings tell you the most voltage and current the relay can handle. If you use the wrong ratings, the relay might break or be unsafe. The table below shows some example values for a relay:

|

Parameter |

Example Relay (Omron G6J-2P-Y DC12) |

Explanation |

|---|---|---|

|

Coil Voltage |

12 V |

Matches the drive circuit |

|

Coil Current |

12.3 mA |

Ensures the coil energizes properly |

|

Contact Current Rating (AC) |

0.3 A at 125 VAC |

Maximum AC current the contacts can switch |

|

Contact Current Rating (DC) |

1 A at 30 VDC |

Maximum DC current the contacts can switch |

Matching voltage and current helps stop the coil from getting too hot. It also keeps the contacts from getting damaged. Relay datasheets show these ratings to help engineers pick safely. If you go over the limits, the relay will not last as long.

Contact Materials

The contact material changes how well a relay works and how long it lasts. Different materials are good for different jobs. The table below lists some common contact materials and what they are used for:

|

Contact Material |

Common Usage/Application |

Reasons for Use / Properties |

|---|---|---|

|

Silver Cadmium Oxide |

Inductive and motor loads |

Resists welding and erosion from high inrush currents |

|

Silver Tin Oxide |

Large peak inrush currents |

Better arc erosion resistance; harder but less conductive |

|

Silver Nickel |

General-purpose, resistive loads |

Hardens silver; resists electrical erosion |

|

Fine Silver |

High conductivity needs |

Best electrical properties; not for low-level switching |

|

Gold and Palladium Alloys |

Low-level or dry circuits |

Resist oxidation; low noise; limited current capacity |

|

Tungsten |

High voltage, repetitive switching |

High melting point; resists arc erosion |

|

Mercury |

Mercury-wetted reed relays |

Good conductivity; no material transfer; for low current switching |

Engineers pick contact materials based on the load and how often the relay switches. For example, silver cadmium oxide is good for motors. Gold alloys are better for small, sensitive circuits.

Reliability

Reliability means how long a relay works before it fails. Engineers use tests and models to guess how long a relay will last. These tests check how the relay handles shaking, heat, and other tough conditions. The table below lists some ways to measure reliability:

|

Reliability Metric / Test Type |

Description / Purpose |

|---|---|

|

Weibull Distribution + Generalized Eyring Model |

Models time-to-failure data under stress |

|

Mechanical Robustness Tests |

Checks vibration and shock endurance |

|

Environmental Robustness Tests |

Tests resistance to temperature and humidity |

|

Accelerated Life Tests (ALTs) |

Applies stress to predict failures faster |

|

Failure Mode Analysis |

Finds and studies possible failure causes |

Relays can fail if contacts stick, fuse, or wear out. The coil wire can also break, or contacts can short. Using the right voltage, current, and contact material helps stop these problems. The electromagnetic field from the coil must stay within safe limits. Some engineers talk about emf when they mean the force that moves the armature.

Tip: Always check relay ratings and test results before using a relay in important jobs.

Applications

General Purpose Use

Electromechanical relays do many jobs in today's electrical systems. They work like switches that use a magnetic coil to move contacts. This setup lets a small signal control a bigger power circuit. People use these relays in cars, home machines, lights, phones, and factory controls. They help run things like motors, lights, and heaters.

Some main uses are:

Turning on big circuits with small control signals.

Keeping control and switched circuits apart, which keeps electronics safe from high voltage.

Making jobs automatic, like starting motors, turning on lights, or running heaters and coolers.

Helping devices handle power safely and easily.

Electromechanical relays have many good points for general use:

They can work with many kinds of signals, from low to high voltage and current, and even very fast signals.

Their strong contacts can handle sudden surges from extra charges in wires and circuits.

They give good electrical separation, which keeps people and equipment safe.

Their simple build makes them cheap and dependable, even if they switch slower than solid-state relays.

Note: The magnetic field from the coil is very important for how the relay works. This field moves the contacts so the relay can safely switch circuits.

Quality Assurance

Companies test electromechanical relays to make sure they work well and last long. They check how reliable the relays are by switching them on and off many times. They also test the relays in hot, cold, wet, and shaky places. These tests help find weak spots before people buy the relays.

Quality teams look for:

Switching that works the same every time.

Contacts that stay strong and do not wear out fast.

Good performance when the relay faces stress, like high current or voltage.

Engineers also check how well the relay keeps circuits apart and how fast it works. They use these test results to make better relays in the future. Some tests look at emf effects, which can change how the relay moves its contacts. Good testing makes sure relays are safe and work well in real life.

Electromechanical relays, called EMRs, work as strong switches. They use an electromagnetic field to move contacts. This helps them control circuits safely. EMRs are not the same as electronic medical records. They are also different from electromagnetic radiation. EMRs help electrical engineers control power in safe ways. They also help new technology grow and improve.

If you want to learn more, read 'Engineering Essentials: Relays and Contactors' by Leland Teschler. Engineers make EMRs better by using new materials and smart designs. Knowing how EMRs work helps students and workers build safer systems. Studying emf and relay technology is still important for new ideas in the future.

FAQ

What are medical records and how do they help patient health?

Medical records keep track of patient information. They include things like health history, test results, and treatments. Doctors look at these records to see changes in health. Good records help doctors make better choices for care. Hospitals keep these records safe to protect privacy.

What is the difference between electromagnetic radiation and medical radiation?

Electromagnetic radiation is energy that moves in waves. It includes X-rays, visible light, and radio waves. Medical radiation uses some of these waves, like X-rays, for health tests. Doctors use medical radiation to learn about a patient's health. Both use energy, but medical radiation is for health care.

What data do electronic medical records contain?

Electronic medical records store patient information on computers. They have health history, test results, and treatments. These records help doctors see all health facts in one place. Hospitals use them to keep patient data safe and easy to find.

What role do health records play in patient safety?

Health records give doctors important facts about a patient. Good records help stop mistakes in care. Hospitals use them to track treatments and check for allergies. Keeping good records helps protect patients and keeps them safe.

What is the importance of radiation safety in medical health care?

Radiation safety keeps patients safe during medical tests. Doctors use medical records to choose the right amount of radiation. Hospitals follow rules to keep radiation levels safe. Good safety steps protect patients and keep records correct.

See also

What Is the Full Name of SSR in Electrical Systems

7 Best Solid State Relay Manufacturers and What Sets Them Apart

Why Choose Solid-State Relays for Modern Applications

What Is a Solid State Relay and What Does It Do